Supporting Students in the International Tractor Design Competition

Providing our MSE02 for an international competition

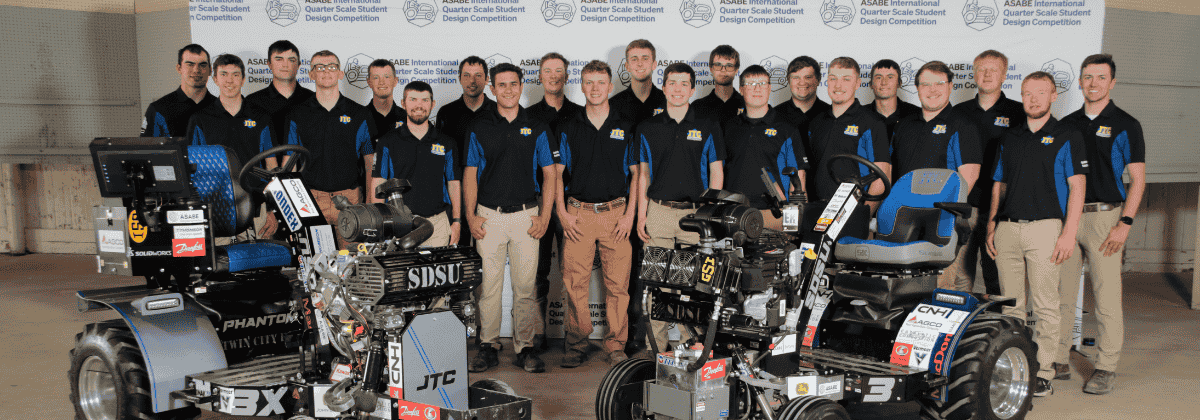

Poclain supported the next generation of engineers by partnering with South Dakota State University (SDSU) in the 28th annual International Quarter-Scale Tractor Student Design Competition, held from May 30 to June 1 in Peoria, Illinois. This event brought together 23 university teams from across the United States and Canada to design and build a fully functional tractor from the ground up.

To help SDSU rise to the challenge, Poclain donated an MSE02 hydraulic motor, a compact, high-performance solution known for delivering high torque in demanding off-road applications. The MSE02 was at the heart of the team’s bold decision to develop a hydrostatic transmission, an innovative choice that set them apart from many competitors.

Choosing a hydraulic drivetrain for smooth operation

The competition provides each team with a standard 34 HP motor and a set of tires. From there, students must design, build, and assemble the rest of the tractor, ensuring it can withstand rigorous durability, maneuverability, and pulling tests. SDSU’s team went beyond the basics by developing a custom hydraulic drivetrain using off-the-shelf components : valves, hoses, pumps, and motors, along with their own software to manage performance.

It’s as simple as driving a riding lawn mower

As the load increased during the pulling challenge, the system automatically adjusted to deliver more torque, ensuring smooth and efficient operation. “You push the gas and you’re going. The software is doing all the work behind the scenes,” added Jaydon Estebo.

A tractor built for performance and comfort

The results speak for themselves: SDSU placed 1st in both the written report and oral presentation, earning a perfect score of 500 points in each category. The team also finished 4th in the pulling challenge, proof of the performance and reliability of their hydrostatic system powered by the Poclain MSE02 motor.

Among the five teams that opted for hydrostatic transmissions, SDSU achieved the best pulling results. The judges also praised the team’s attention to detail and innovative approach to system integration, as well as the thoughtful design and operator comfort. The machine featured a custom air-ride suspension seat and centralized controls on the armrest, offering a user-friendly experience rarely seen in student-built prototypes.

This project is a shining example of how Poclain’s technology empowers students to explore new engineering solutions and push the boundaries of what’s possible in compact off-road machinery.

For more information, contact us.