[Case Study] HEVO Revolutionizes Heavy Compaction Efficiency

At Poclain, with over 60 years of experience as a leading transmission solutions provider, we've reimagined the hydraulic motor. We have analyzed real-world usage in construction, industrial, agricultural and forestry applications to develop HEVO – a game-changing suite of technologies. This case study focuses on how HEVO optimizes heavy compaction.

Heavy compactor manufacturers typically define gradeability between 35% and 40%. This figure heavily influences transmission sizing. However, compactors spend most of their time on flat ground.

Understanding Real-World Compactor Usage

Field data reveals that compactors operate at pressure levels below 100 bar for the vast majority of their working life. Max torque the basis for traditional sizing, occurs less than 0.1% of the time. Ironically, this max torque also dictates the design point for these machines.

HEVO: A Disruptive Approach to Max Torque Events

HEVO takes a radically different approach. Instead of sizing for the maximum torque point, HEVO sizes for efficiency and addresses peak torque events differently.

For the 13 tons tandem roller of this study, a 1,370cc/rev displacement motor is sufficient to replace a 2,800cc motor. This allows us to optimize the design for the most common operating conditions.

Conquering Slopes: The HEVO Solution

How does HEVO handle the torque needed for inclines while meeting the demands of heavy tandem rollers?

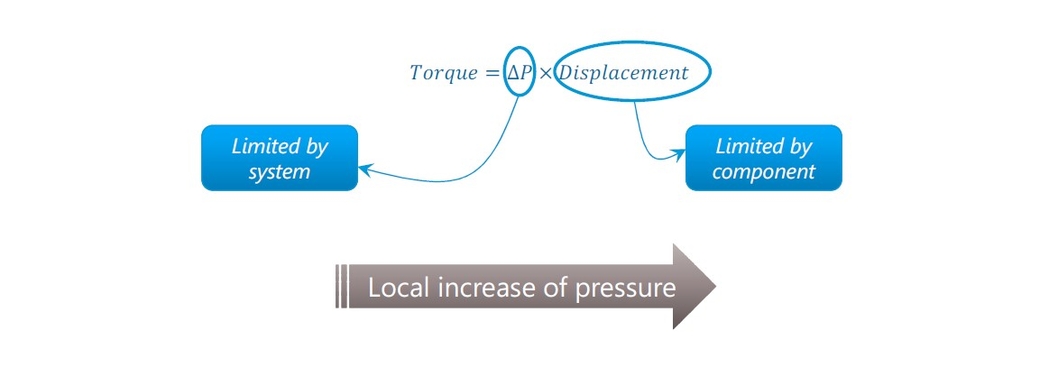

To deliver the necessary peak torque for inclines, HEVO incorporates a unique pressure booster within the hydraulic motor. This Poclain-engineered booster, along with integrated control valves, seamlessly and automatically increases pressure locally within the motor.

The result?

Amazing performance with 400 bar inlet capability, 800 bar maximum outlet pressure, and low flow ripple. The system remains transparent to the user, with automatic activation and deactivation.

Customer Benefits: Efficiency and Fuel Economy

HEVO is designed around a comprehensive understanding of compactor usage:

✅ Consistent speed

✅ Smooth acceleration/deceleration

✅ Compaction on inclines

✅ Short distances

✅ Higher speed on-site movement

✅ Significantly higher rolling resistance during compaction

✅ Typical 20-minute work cycle

Based on a 20-minute cycle for a 13 ton heavy tandem compactor with MS18 2.8L (2,812cc/rev) hydraulic motors (39% gradeability), we tested a 1,370cc/rev HEVO prototype with the integrated booster (capable of increasing internal motor pressure from 400 to 800 bar).

The results speak for themselves: on average 10% total fuel consumption reduction in operation.