Poclain Propel Solutions Power The New Generation Of Compact Fire Fighting Robots

Rugged, nimble and dependable in the most extreme conditions, firefighting robots can supplement or fully replace human work in hazardous environments. Known for their reliability, precision and compact envelope, Poclain transmissions have already been chosen to equip fire fighting robots around the world.

Compact Power, Precise Control, Continuous Duty

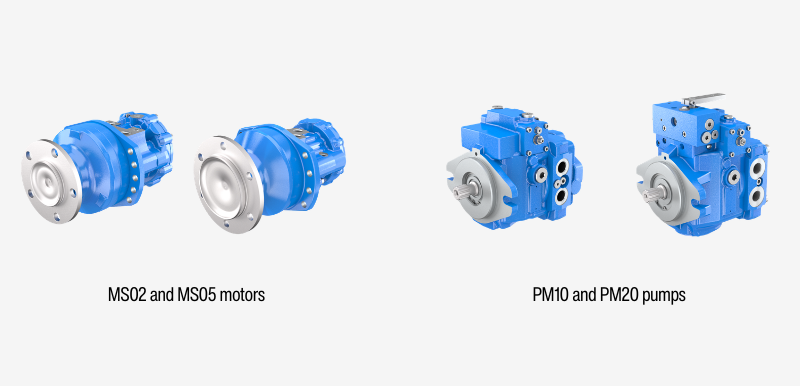

The Poclain PM10/PM20 tandem pump and the MS high-torque radial piston motor are the perfect match for fire fighting robots–a combination engineered for tracked mobility, precise speed control, and reliability.

- High mechanical and volumetric efficiency improves system efficiency and reduces heat, a key benefit for long missions in confined and high temperature environments.

- High working pressure and torque density provide tractive effort for climbing, debris pushing, and hose towing on steep, rubblestrewn sites.

- Wide speed range with dual displacement supports creep for reconnaissance and transit speed between work zones, with integrated parking for safe operation.

- PM pumps (PM10: 7–21 cc; PM20: 21–28 cc) offer electroproportional control for autonomy and teleoperation, tandem configurations, and integrated charge circuits for cavitation-free closed loops. proportional free closed loops.

A Rugged Fire Fighting Robot with Integrated Poclain Transmission

In 2023, a North American fire fighting robot OEM sought to reduce size and improve efficiency on a dieselpowered tracked platform capable of stair climbing, door breaching, zeroturn maneuvering in tight stairways, and delivering high water flow equivalent to multiple operators on a hose line. A more compact, integrated transmission was essential.

The OEM chose Poclain’s solution:

- PM10 tandem pump to optimize package size and deliver precise closedloop control;

- Two maintenance-free MS02 two-speed motors with integrated brakes, replacing an inhouse braking concept and simplifying manufacturing and upkeep.

Performance gains: Lower circuit temperatures through high volumetric efficiency, improved low speed manoeuvrability, integrated hydraulic braking, and robust twospeed capability for versatility.

Outcome: The integrated Poclain transmission made the robot more robust, simplified production and maintenance, and improved operational performance, while keeping the system compact and mission-ready.

Autonomous Agricultural Robot Project

A recent autonomous agricultural robot project demonstrated that the Poclain transmission was the ideal to preserve terrain, drive precisely in narrow crop rows, and climb 45% slopes at controlled speeds. The transmission and its benefits relate directly to compact fire fighting robots where light weight, precision, and autonomy are critical.

Solving Track Drive Synchronization Reliably

Left/right synchronization can be an issue on tracked robots, causing the vehicle to drive erratically and increase thermal load. The Poclain transmission addresses this at three levels:

- Hydraulic symmetry: Matched PM pump sections with equivalent control maps and balanced charge circuits reduce drift and differential pressure.

- Motor valving: Motor dual displacement is synchronized to mission mode (low/high) and the integrated brakes stabilize transients during stop/start cycles.

- Smooth braking: with electronically controlled pumps, brake application and release is smooth, preventing rebound, jerks and rollbacks on slopes.

- Electronic control layer: Electroproportional control of each loop, closed loop speed sensing on motor and software bias/ trim ensure straight tracking under load, with failsafe braking if energy is lost. This is key for autonomous and teleoperated robots proportional loop speed sensing motor safe.

Why Chose Poclain for Fire Fighting and Emergency Robots

All-terrain precision: The transmission enables to drive in confined spaces and slopes above 45% at consistent speeds; it preserves ground integrity and enables precise path following.

- Efficiency at scale: Our camlobe radial piston design delivers high efficiency and smooth low speed operation, limiting heat during extended missions.

- Control flexibility: the PM pump supports mechanical, servohydraulic, and electroproportional controls, plus a tandem setup for tools and ancillaries.

- Global support network: Operations across three continents with research and development, plants, and sales subsidiaries—ensuring technical support and rapid supply wherever you operate.

Whether you build smoke exhaust robots for tunnels, fire suppression units for petrochemical plants, dewatering robots for flood control, or wildland firebreak robots for mountainous terrain, Poclain’s compact transmissions deliver the torque, controllability, and endurance your mission requires—from 2 ton microplatforms to 5 ton heavyduty robots.

Our Specific Offer: Complete Propel Solutions For Robots Up To 5 Tons

We cover the full range of small to mid-size fire fighting robots with a transmission offering that adapts to your chassis, control type, and duty cycles.

WEIGHT CLASS | ||||

| Up to 2 tons | Up to 2 tons 4WD | 1.5-3 tons | 3-5 tons |

Typical use | Reconnaissance / fire | Fire fighting robots | Pumping, dewatering | Wildland firebreak robots |

Pumps | PM10 tandem configurations | PM20 tandem set for | PM10 tandem | PM20 tandem pumps |

Motors | MS02/MSE02 with integrated brakes and dual displacement | MSE02 with integrated | MS05/MSE05 for high tractive loads and | |

To know more, contact us.