Mini-Loaders : an All-In-One Direct Drive Transmission System

An All In One Transmission System

Poclain provides a complete hydrostatic solution, highly recognized in the market, maintenance-free and offering outstanding traction control and reliability for Mini-Loaders. It delivers multiple advantages compared to axle machines for your multi-functional mini-loaders.

OUR STANDARD SOLUTION

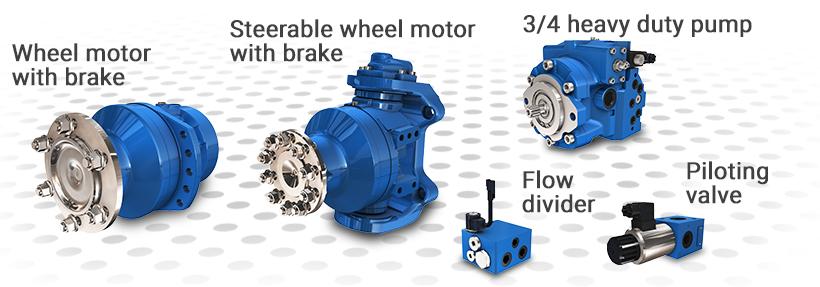

- Serial circuit

- Four wheel motors

- One variable displacement closed loop ¾ heavy duty pump with automotive, hydraulic or electronic control

- Mechanical and hydraulic inching

- One piloting valve KVC for brake and gear speed

- One serial protection block for anti cavitation and safety

AVAILABLE OPTIONS

- Integrated steering pivot motor

- Hydraulic automotive control

- Electronic automotive control with embedded software for higher accuracy

- Speed sensors

- Flushing valve

- Integrated multi-disc parking brake

- Parking brake valve

Direct drive MS and MG motors meet your Mini-Loaders' needs

Poclain Hydraulics direct drive cam lobe motors meet your four-wheel drive mini loader’s needs with 300 modular combinations, compact envelopes, high efficiency and a backlash-free design. No gearbox means no mechanical loss in the gears. Cam-lobe technology assures heavy duty, precise movement and constant speed. Motors are available with single or dual displacements. Various wheel flange bearing supports are available for different rim sizes with or without parking brake.

For an articulated machine, we propose four MS motors.

For a one-piece chassis mini loader, we propose four steerable MG motors. The integrated C-frame with hydraulic pivot offers an enhanced steering angle, to increase machine stability and avoid twisting high-pressure pipes. By combining components (bearing support, brake and c-frame), MG motors reduce potential failure points and external brake stress, while reducing tire wear and fuel consumption.

PM hydraulic pump for your mini-loaders

The Poclain Hydraulics PM pump range completes the mini-loader package. With a wide range of displacements, the PM pumps’ reinforced structure increases robustness and reliability for high performance and 420 bar peak pressure. The PM pump delivers a complete range of controls with or without feedback. Its compact dimensions, modular design and interchangeable options simplify machine integration.

WHAT DO YOU GAIN?

- High maneuverability with simple and reliable wheel drive solution versatility

- Reduction of ground damage thanks to anti-skid system

- Reduced fuel consumption

- Less parts management and maintenance cost compared to axle solution

- Increased operator safety due to a lower center of gravity (vs axles machines)

- Increased machine payload compared to similar weight class (vs axles machines)

- Wider flexibility in the machine design features (narrow dimensions)

Flexible Design

Easy Integration with Free Space Between Wheels

Productivity

Optimized Traction Control in Any Condition

Reliability

Poclain Hydraulics as Market Reference & Leader in Hydrostatic Transmission for Mini-Loaders

Precise maneuverability

Poclain Hydraulics direct drive radial piston motors easily maneuver your machine regardless of weather or terrain, such as mud, sand and snow. MG motors improve productivity and ability to make U-turns with fewer movements, beneficial in construction or landscape work in tight spaces. They also enable front-wheel or crab steering with an easy-to-integrate, flexible, compact design. Our four-wheel-drive propel solution ensures minimal surface disruption. Serial circuits deliver an anti-skidding effect, alternating front and rear 4-wheel drive to restore traction. Poclain Hydraulics PM pumps, with automotive or hydraulic control, delivers flow to the circuit, and a VB parking brake valve is an available option.

Machine stability & security

The wheel motors enable designers to deliver a lower machine center of gravity, increasing security and operator safety. MS and MG motors both free up design space, and the MG motors include a steering pivot for one-piece chassis architecture and less part management.

Optimized capacity

Direct drive four-wheel transmissions are lighter than an axle, increasing machine payload capacity when compared to a similar weight class. Mini-loader OEMs gain compactness and efficiency.