Cleanliness Training Program: Poclain support its Suppliers

The training focused on ISO 16232:2018 and VDA 19.1/19.2, internationally recognized standards for measuring and reporting cleanliness levels in components used in road vehicles. A critical benchmark for Poclain, as cleanliness directly impacts the performance and lifespan of hydraulic components such as motors, pumps, and valves.

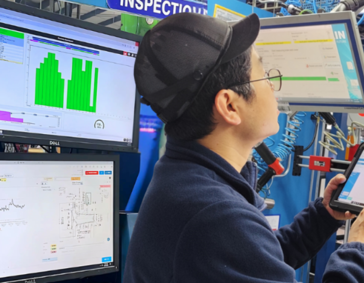

Poclain brought together 36 representatives from 18 companies in India, supplying multiple Poclain factories, for a one-day technical training session, focused on industrial cleanliness standards. This initiative reflects Poclain’s ongoing commitment to quality, customer satisfaction, and supplier development across its global operations.

Shared Standards for a Global Supply Chain

While the event was held in India, the impact reaches far beyond. The participating suppliers deliver machined castings and forgings not only for Poclain’s Indian operations, but also for sites in France, Italy, the USA, and the Czech Republic. Ensuring consistent quality across this international network is essential to meeting customer expectations and enhancing product durability.

The training focused on ISO 16232:2018 and VDA 19.1/19.2, internationally recognized standards for measuring and reporting cleanliness levels in components used in road vehicles. ISO 16232 is a critical benchmark for Poclain, as cleanliness directly impacts the performance and lifespan of hydraulic components such as motors, pumps, and valves.

Led by external expert Samir Rout, the session covered:

- Clean facility design principles

- Staff responsibilities and mindset toward cleanliness

- Environmental monitoring using Illig Analysis

- Blank level and declining tests

- Selection of analysis filter membranes

A Strategic Investment in Supplier Development

This was the first event of its kind organized by Poclain in India, and it marks a significant step in the company’s supplier improvement and development program. The goal: growing supplier competencies and elevate quality standards across the supply chain.The session was coordinated by representatives from Poclain’s supplier quality assurance, supplier quality development, and sourcing departments.

Building on the success of this session, Poclain aims to foster supplier excellence through regular reviews and collaboration, sustaining this momentum and reinforcing best practices across its supply chain to guarantee best-in class products for our clients.

For more information, contact us.