CreepDrive™

The CreepDrive™ system ensures low constant speed in work mode and it provides to a driver a better control on the work itself. Vehicles equipped with CreepDriveTM feature two independent transmissions: the standard mechanical one – traveling mode and a hydrostatic one – work mode.

MAIN BENEFITS

- Same vehicle for work and travel mode

- Independent of engine speed

- Low engine speed - low noise level

- Reduces brake, clutch and transmission wear

- Compatible with automatic and manual gearbox

- Simple design easy to install on the standard truck. Simple maintenance

- Compatible with diesel, gasoline and LNG

- Truck versatility

- Improved quality of work

- Driver’s comfort

- Maximized fleet productivity

- Prevalidated solution

Poclain Hydraulics offers CreepDrive™ system in two sizes, CreepDrive™ 1 and CreepDrive™ 2.

Shifting from one to the other is done by activating a switch. The mechanical transmission is used for traveling on the road, while its hydraulic counterpart is used for working at low speed.

INSTALLATION

- Easy to fit on any kind of trucks

- The motor fits between the gearbox output and the axle, two new cardan shafts are required - max. angles of the cardan shafts must be checked

- The pump is fixed on the PTO with four-bolt interface, ECU is managing the torque limitation of the PTO

- ECU and software are developed and supplied by Poclain Hydraulics, and adjustable by the customer

- Customer is responsible for supplying and installing the pneumatic components, hydraulic tank, cooler, piping, filtration and hydraulic oil with the assistance of Poclain Hydraulics

- ECU role:

- Monitoring of the system preventing overpower or overtorque

- Management of clutch, declutch sequences

- Communication with the truck and additional equipment

- The system is customized to the application with parameter settings

OPERATION

- The vehicle brake must be applied and the mechanical transmission set to neutral, while the engine PTO is engaged to drive the pump that supplies flow to the system hydrostatic motor

- A switch located in the cab engages a pneumatically controlled mechanical clutch, which sets the mechanical transmission to neutral and engages the hydrostatic transmission

- The driver sets the engine speed to the desired working rpm and, after releasing the brake, moves the joystick in the desired direction

- Consistent low working speeds are achievable in both forward and reverse directions

- When traveling at on-road speeds, the PTO clutch is disengaged and the mechanical transmission works at appropriate speeds

MAINTENANCE

- Hydraulic components must be filled with oil before first start

- Hydraulic oil must meet the Poclain Hydraulics requirements regarding cleanliness, viscosity and oil type

- Based on duty cycle and truck performance, CreepDrive is sized for the truck lifetime. The oil has to be drained according to the duty cycle

|

CreepDrive 1 |

CreepDrive 2 |

|

|

Trucks range |

Up to 44t (97,000 lb) |

Up to 44t (97,000 lb) |

|

Hydraulic motor |

||

|

Hydraulic pump |

PM, pump with EP control and mechanical feedback |

PM, pump with EP control and mechanical feedback |

|

Valves |

VE60 , KVC3/2 |

|

|

ECU+SW |

Electronic kit (ECU, SW, display, joystick, wiring,…) or stand-alone components |

Electronic kit (ECU, SW, display, joystick, wiring,…) or stand-alone components |

|

Speed |

From 0,4 kph up to 10 kph (0.25 to 6 mph) |

From 0,4 kph up to 12 kph (0.25 to 8 mph) |

|

Max power |

95 kW (125 HP) |

105 kW (140 HP) |

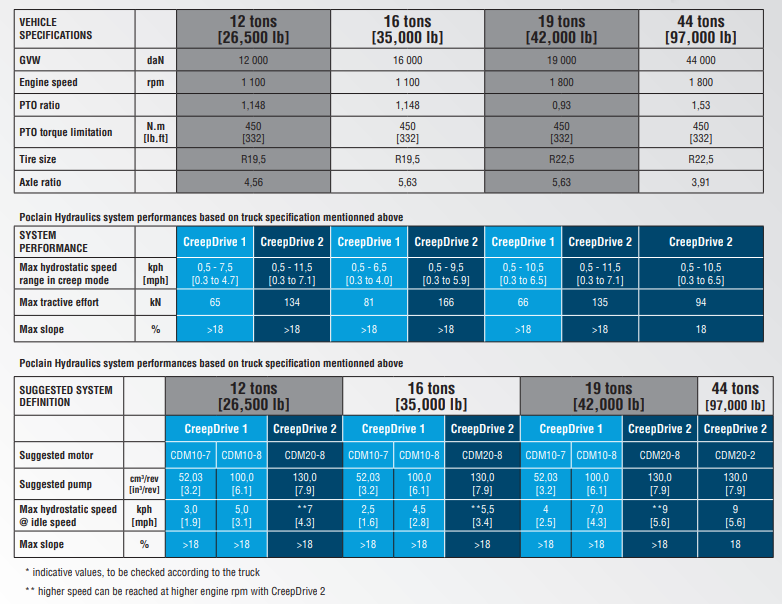

The following tables represent an extract of the possibilities of system combinations, motors and pumps portfolio. Please refer to your local Poclain Hydraulics application engineer to learn more about the offer.

The main applications for CreepDrive™ system are trucks either working on-road or on-rail.