[Case Studies] A New Low Profile Utility Vehicle For Underground Mining

Poclain Hydraulics has been active in Southern Africa for over 30 years and has provided hydrostatic transmissions to several OEMs in the region. Since 2015, we decided to have a permanently based sales engineer stationed in South Africa and his focus is to travel throughout Southern Africa to support our business.

Against this back-drop, Jan Lotz has been key in securing new business in Botswana and helping UV Botswana design a new hydrostatic transmission for their 6T low profile underground mining utility vehicle platform.

UV Botswana, underground mining vehicle

UV Botswana (Pty) Ltd is a 100% locally-owned private company which was established in 2005. They specialize in the design and manufacture of low profile, trackless utility vehicles, offering a broad range of innovative and robust underground UVs to cater for a variety of mining, supervision and support activities.

The company boasts new and state-of-the-art manufacturing facilities in Francistown, Botswana. At this modern plant, they provide a full service offering including research and design; engineering and manufacturing; commissioning, field service and full aftersales service backup.

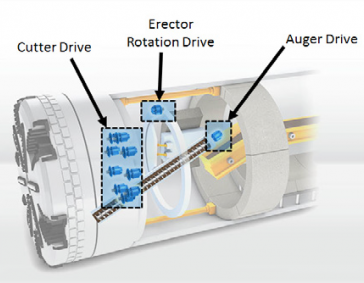

The MV-U60D CC machine

The MV-U60D CC machine is a low-profile utility vehicle that can carry and move a range of multi-functional cassettes into and around the underground mining area. Individual cassettes are loaded onto the machine for a variety of tasks - including general purpose transport, transporting of bulk emulsion explosives, diesel fuel, oils and other fluids. Cassettes can carry loads of up to 6T, and the OEM can also design and build cassettes to meet the specific needs of their customers.

The first prototype of this machine was commissioned in mid 2022 and the vehicle is now in serial production. Orders for the machine are growing as more and more mines see the competitive advantages which this machine can bring to their operations.

A complete hydrostatic solution powered by Poclain

This machine is a four-wheel drive vehicle that relies on a complete Poclain Hydraulics hydrostatic solution. The drive system includes a tandem PM50 pump with automotive control, four MS11 wheel motors, as well as brake valves. Antiskidding features of the machine are provided by having two independent closed loop hydraulic circuits – each consisting of one pump and two hydraulic motors, driving two wheels each.

The brake system

The machine’s service braking system consists of a foot brake pedal and brake valve which provides a first level of hydrostatic braking by inching (de-stroking) the pump and at the end of the pedal stroke, the front wheel motors multidisc service brakes get activated.

The MS11 front wheel motors include Poclain Hydraulics’ “S” type wet multidisc service brakes which are integrated in the bearing supports as well as our “T” type spring-applied and hydraulically released (SAHR) Park/Emergency brakes at the rear end of the motors. The rear motors just include our “P” type SAHR park/emergency brakes, which are also located in the bearing supports of the motors.

Jan LOTZ

Sales Engineer

Poclain Hydraulics South Africa

Contact us