Advanced Drive Technology

As the business environment rapidly evolves, Poclain is gearing up for the next phase of its transformation. We have undertaken a comprehensive “voice of the customer” (VOC) campaign to better undertsand the significant trends affecting our key customers. We deployed our senior managers to engage with over 50 off-highway customers and distributors from various regions and market segments.

It became clear that all customers are concerned with issues related to sustainability, the transition to electric drives, shortages of skilled labour, intensified competition due to new market entrants and the regionalization of marketplaces. Topics such as functional safety, machine operation simplification and transparency and automation are becoming increasingly crucial, creating demand for innovative software and sensors.

The marketplace is becoming more demanding, requiring OEMs to achieve both Advanced drive technology greater productivity and sustainability while also focusing on lifetime monitoring and repairability of components. Moreover, OEMs seek to differentiate themselves by maintaining exclusive control over their HMI features. Our customers are, however, willing to partner with companies like Poclain that can accelerate project timelines in an era of resource scarcity and complex market demands. They are open to suppliers capable of providing essential machine sub-functions that seamlessly integrate into overall machine architectures.

Poclain’s main innovation programs align strongly with this VOC feedback. We view it as our responsibility to deliver “augmented components and solutions” that our customers can easily incorporate into their machines, addressing primary transmission requirements concerning sustainability, productivity, and market readiness. Although Poclain operates across multiple market segments, we have directed our innovation policy along two main paths, ensuring both activities develop in parallel to leverage potential commonalities.

The first direction focuses on developing an array of electric propel solutions, while the second involves creating the next generation of hydraulic radial piston motors.

Bauma Munich 2025 will be a remarkable event for Poclain. We’ll not only showcase our latest transmission solutions for key markets like skid steer loaders, mini and compact tracked loaders, small articulated wheel loaders, mini excavators, and compaction equipment but also reveal our newest innovations. Our booth will feature an area focused on full electric vehicles and high-performance hydrostatic solutions. It is crucial for us to align with our customers’ technology roadmaps by sharing our main product strategies openly.

Resilient hydraulics

There are several markets where hydrostatic transmissions will continue to be the preferred technology for many years. With this understanding, Poclain has introduced a new generation of cam lobe motors. A mock-up teaser for the program, Hevo, was unveiled at the latest Agritechnica. Meanwhile, several prototypes are being tested on real customer machines, and our marketing department has defined specific segments.

The Hevo Booster range is designed for wheel-type applications that experience high torque peaks and require limited speed. The concept is straightforward: the motor operates on a small nominal displacement sufficient for more than 90% of its usage time. When torque peaks occur, an internal pressure booster activates, potentially doubling the pressure inside the main cylinder block up to 800 bars for a short duration. The internal components have been upgraded to withstand these high pressures, but the external hydraulic system, including pumps and hoses, only deals with the standard system pressure of around 400 bars. This technology’s primary benefit is that customers can design their circuits around a small displacement motor that runs at high pressure and low flow most of the time, ensuring high system efficiency. However, the booster can engage as needed to help the transmission handle external loads smoothly without shocks, similar to a CVT gearbox.

The Hevo Dual range is targeted at tools that need to operate at high speed to achieve high productivity levels, while keeping enough torque to address high resisting loads. Key applications include drilling machines and forestry head processors where working time is crucial. The Hevo Dual is a two-displacement motor designed to run most of the time in its smaller displacement to maximize energy efficiency through high pressure and low flow conditions. What sets Hevo Dual apart is its ability to handle high power at high speeds for long periods of the duty cycle due to a novel oil distribution method within the motor. When small displacement is selected, longevity is not compromised as all cam lobes and pistons “work” (produce torque) throughout each revolution, distributing stress evenly across all parts of the motor.

The first Hevo motors to be released to the market will be the Hevo Booster in the 20,000Nm and 6,000Nm ranges, and the Hevo Dual in the 5,000 to 10,000Nm segment. Full-scale production is scheduled for 2026.

Advancements in e-mobility

Following our initial introduction of electrohydraulic drives that continue to use our unique cam-lobe radial piston wheel motors at the last Bauma, we are excited to now present our e-Wheels. These all-in-one motors closely resemble our well-known MS wheel motors, offering similar form, integration, torque and speed values, and include all the necessary functions for a high-performance wheel drive. They feature a liquid cooled torque-producing electric module akin to a hydrobase, an integrated brake, and a bearing support capable of handling radial and axial loads.

These innovative e-Wheel transmissions are the result of five years of intensive work and cooperation of several teams and competence centers, some of which joined Poclain following recent acquisitions. The transmission inverters are produced by Emsiso, our new company based in Maribor, Slovenia, which specializes in high power density inverters for both low and high voltage systems covering a range of 5kW to 100kW. Our Maribor location has developed an extensive system functional safety expertise over its 15-year existence, and the e-Wheel transmissions comply with the ISO 25119 standards for vehicle safety.

The e-Wheel transmission e-Motors are designed and produced by Moteg: our new majority-owned competence center located in Flensburg, Germany. Moteg specializes in compact PMSM (permanent magnet synchronous motors) which are primarily used today in electrified trucks and buses to drive oil pumps or air compressors.

At Bauma, we will showcase the first size of e-Wheels, dubbed eW30, which provides torque of around 2200Nm and speeds up to 200rpm measured at the wheel. The initial applications for these motors target the very compact segment of machines below 25kW. Poclain is engaged in several customer projects with manufacturers of machines such as small articulated loaders, truck-mounted forklift trucks and small site dumpers. Our e-Wheels can be mounted on the same chassis as our existing hydraulic MS wheel motors, offering OEM customers an attractive alternative between conventional ICE, electro-hydraulic or fully electric drive architectures with very similar mechanical interfaces.

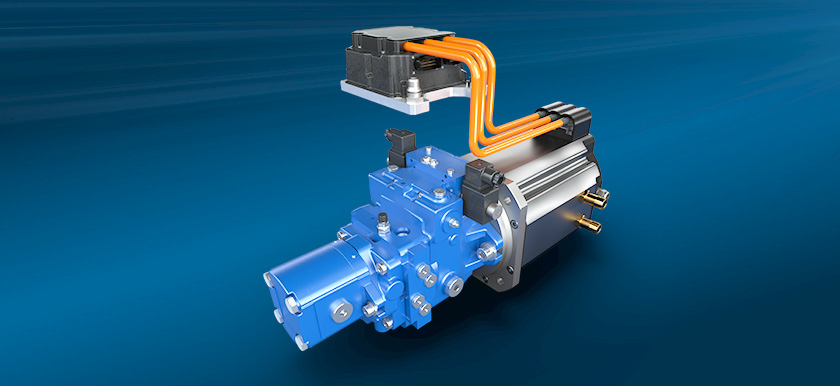

Poclain believes that electro-hydraulic transmissions still have a place in vehicles that require limited energy consumption, either due to short operational hours or because their duty cycle demands more torque than speed. This leads to a limited power requirement for the transmission such as lifting rather than travelling. A good example of such machines, where electro-hydraulics could remain advantageous long-term, are small 2-3T asphalt rollers that rarely operate for more than three hours a day. One of the new features Poclain will present at Bauma is a new type of pump control. It has been designed specifically for electrically driven hydrostatic pumps that rely on contactless sensors for precise control of swash-plate position and safe operation.

Meeting the needs of OEMs

The convergence between our latest hydraulic and electric innovations can be considered from various perspectives and involves the areas of machine integration, simplification, productivity and sustainability.

OEMs need to design machines that can support ICE transmissions, hybrid electro-hydraulic drives or full electric setups on the same chassis. Our e-mobility program has been designed for wheel motors with this kind of interchangeability in mind, irrespective of hydraulic or electric technology. Moreover, both our Hevo motors and our e-Wheels lean themselves to an easy integration as they contain multiple functions in one unit, easing the OEM’s assembling tasks.

Our newest motors have been designed to assist drivers in devoting more of their attention to the tools they need to operate and less to the powertrains. Hevo Booster motors or e-Wheels can provide variable torque and speed based on terrain resistance, eliminating the need for active gear shifting actuation. Hevo Dual motors or e-Drive Software for electrohydraulic transmissions come with autoshift functions that automatically select the best gear to optimize energy consumption as well as productivity without the driven noticing the shift.

When it comes to sustainability, our next-generation hydraulic motors operate efficiently with less flow for a given speed and minimize losses at higher speeds and pressures, saving energy for longer working shifts. The e-wheels designed for carbon free operation and high efficiency transmissions allow to prolong the battery range and to generate more output from the machines.

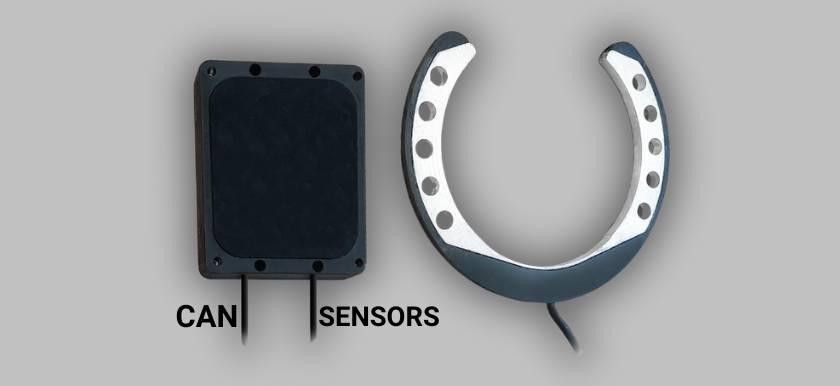

Control software architecture and advanced sensors can also be shared between electric and hydraulic motors to ensure the same level of accurate control, safety and automation. Our latest innovation is a sensor-equipped washer, fitted between the wheel motors and the chassis to measure the loads in several directions. The sensors are connected to an electronic unit that delivers real-time information to the vehicle CAN. This signal enables the OEM, particularly in applications where there is a risk of tipover, to alert the driver or take control of the machine to guarantee its stability. The system is compatible with our latest-generation hydraulic and electric motors.

The increasing convergence between hydraulic and electric technologies is underway at Poclain and fully in line with our new motto, “Poclain: hydraulics and beyond”. We want to convey to our customers that Poclain is not giving up on innovation in hydraulics while also expanding its scope, reflecting a broader, more agnostic approach to drive technologies while maintaining our commitment to performance and customer service.