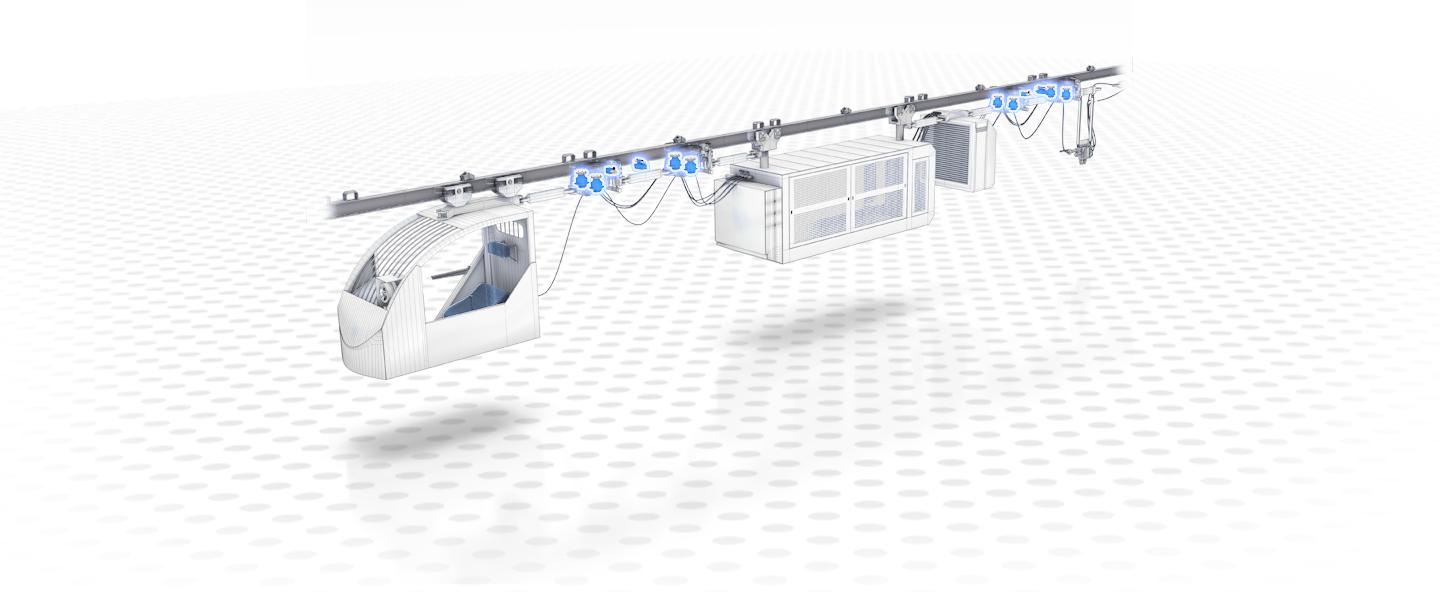

Suspended Locomotive

As a suspended locomotive OEM, you face a multitude of design challenges. Space constraints, increasing safety regulations, end user productivity needs and complex I beam routes challenge design. Poclain can help you throughout your suspended locomotive's design process. Deliver efficient and safe machines to meets your end user’s safety, maintenance, and productivity expectations.

Our main transmission solutions for suspended locomotives include two different technical solutions:

- A friction wheel on an I beam

- A rack and pinion mechanism

Both compatible with our direct drive solution. Either an MS05 or MS18 motor drives the transmission. Your machine may need a bypass valve depending on the size and equipment transported.

Compact solutions to meet design needs

Poclain Hydraulics direct drive solutions give you high torque in a compact package. This means design flexibility to work with space constraints. One group of motors delivers 20Kkn of traction. A 200kn monorail crane needs 20 motors and a 160kN monorail needs 16 motors.

The direct drive design reduces the number of parts needed for the propel solution. It eliminates chains, belts and gearboxes. This reduces production and logistical costs.

Reduce downtime & maintenance

Poclain Hydraulics motors have a low failure rate. With proven success over years of incorporation into suspended locomotive main transmissions. Our low-maintenance all-in-one motors have fewer potential failure and inspection points. This helps you reduce maintenance hours and downtime due to failures.

Better productivity and controllability

Poclain Hydraulics motors give your machine strong climbing abilities and high torque traveling force. With our propel solutions, your machine can move heavy loads along the I beam safely. The 3V 2H20 bypass valve allows your suspended locomotive to travel at higher speeds. The bypass valve also reduces the total required driving force when transporting smaller loads.

Direct drive solutions eliminate the mechanical losses found in high speed and gearbox solutions. Deliver the redundancy to face unexpected situations including sudden stops, speed increases and the low inertia needed for quick reversals.

Meet safety and stability expectations

Prioritizing personnel and equipment safety is paramount for mining operations. Our motors allow for safe operation in highly explosive environments. Integrated emergency braking helps your users anticipate the unexpected.

Give your users a more pleasant work experience. Our propel solutions help them to focus on their work without added noise. The design of our motors as well as eliminating gearboxes reduces noise pollution.

Radial piston design delivers a smooth, stable ride. This creates a safer environment for both labor and materials in the mine. Our motors are also a good match for remote driving functions for added safety.

Be confident in our ability to support your machine, no matter where you are

Regardless your location, our experts are there for you throughout the development of your suspended locomotive. They provide data, settings help, and prototype delivery on top of an easy-to-integrate solution.

Quality performance is in line with the highest suspended locomotive requirements. With our standard line of production, we deliver the same process and the same level of quality. Our reliable and trusted for suspended locomotive propel solutions equip leading OEM machines.

Training and continuous improvement – Poclain Hydraulics training and support doesn’t stop once your machine goes into series. Our standard or personalized trainings help you ensure your team knows our products and is ready to deliver competent support to your customers.