Tool Drive

Applications with tools drives require some specific needs that radial-piston technology can provide

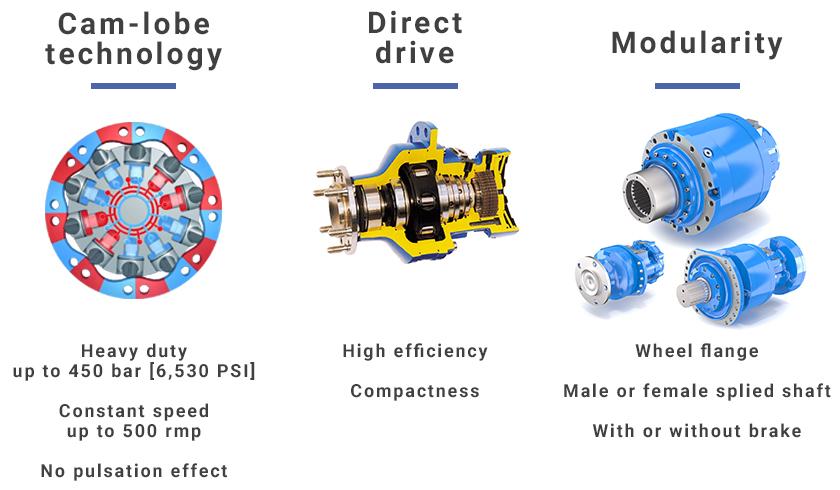

- Full torque even at low speed (< 1 rpm): Better torque control during process. More productivity

- Low inertia: Easy and quick change of rotation direction. Accept shock load and pressure peaks

- High efficiency (up to 95%): Reduced energy consumption. No need to “oversize” the motor

- Compact and low weight (reduced diameter and length): Easier installation on site. More motors for a given space (motors side by side)

- Heavy Duty (qualified at 450 bar and bearing support for high radial and axial loads: Low maintenance cost. “All-in-one solution” (no extra bearing)

- Free-wheeling capability: Possibility to disengage the hydraulic transmission. Increased speed capacity. More speed possibilities on multi-motors drive. Smaller pump size to reach required speed

Poclain Motors are used in CLOSED and OPEN LOOP hydraulic circuits.

Poclain hydraulic motors provide specific features for tool drives

- Various shaft interfaces: males splines, female splines, shrink disk, wheel flange

- Multi speed capability

- Flat ports for valve flanging

For trenchless, recycling and marine applications we provide several system solutions with flangeable valves. These are compact solutions combining several functions in single solution block: anti-cavitation, cross-over relief, counter balance, free-wheeling, flushing etc. The benefit is to provide several integrated function in one solution for customer to save on space and cost (less piping) and increased safety.

For Tool Drives we offer wide range of 6/2 diverter valves (selector valves) up to 300 lpm [79.25 gpm] used for selection between two hydraulic motors or two hydraulic cylinders that do not operate simultaneously. The main development and customer benefit is low pressure drop design that limits the loses in the system.