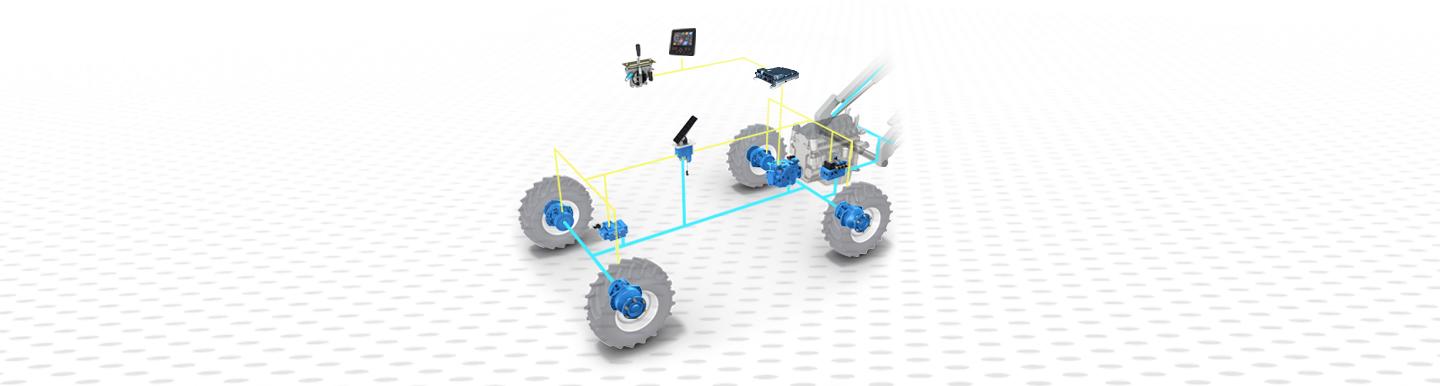

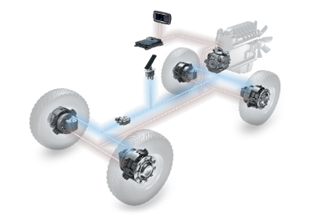

Mobile Hydraulic Transmission

Ready-to-use solutions:

With the CT-SUITE tool, Poclain Hydraulics is making electronically controlled hydrostatic transmissions more accessible by allowing customers to create their own software management. Based on a library of fully tested software functions, each customer can combine all the necessary functions to generate their software in just a few clicks, reducing development time and costs without any further help.

- Travel/Work modes for machines that have to travel fast from one working area to another:

- Use the same hydraulic installation to be able to travel fast between sites while maintaining a high torque transmission at on-site

- Best efficiency in both modes (work and travel)

- Energy saving

- Noise reduction

- Driver comfort

- Work precision

- Anti-Stall to prevent engine stalling when torque requested to engine can exceed the engine capacity:

- Driver stays focused on the work at hand, not on engine management

- No need for oversized engine

- Increased driving comfort

- Automotive Control to drive the machine like a car:

- Automatically adapts the machine’s speed to engine rotation speed.

- Compatible with engines with cable control.

- Increased fuel savings compared to constant engine speed

- Easy to drive and simple to integrate

- Smart Automotive for efficient control of the pump and the engine together:

- Independent engine and pump curves

- Reduces noise emissions

- Increased fuel savings compared to constant engine speed

- EcoDrive™ compatible

- Multi-mode compatible

- Cruise Control / speed control loop control with Smart Automotive, when precise machine speed is needed for working process:

- Driver only focuses on work at hand, not on machine speed

- Better job quality

- Electronic Inching when precise machine approach is needed, or when engine power is needed with very low or null machine speed:

- Precise machine approach

- Engine power needed for tools at very low or null machine speed – better tool management

- Increased driving comfort

- Automatic speed shifting, smooth speed change management when machine needs to switch automatically “on the fly” between high torque (first speed) and high speed (second speed, third speed etc.):

- Easy to drive

- Preserves motors – increased lifetime

- Comfort

- Hydrostatic braking with electronic pedal to adjust hydrostatic braking (mandatory with automotive control):

- Easy to drive (car like)

- Comfort

- Safety

- Combined braking with hydraulic brake pedal (VB) when hydrostatic braking is needed to reach a level of deceleration:

- Better braking performances

- Reduces friction brake wear – increased lifetime

- Hill Start to stop and restart the machine on a slope:

- Easy to drive

- Safety

- Preserves ground

- EcoDriveTM for more environmental (eco) driving with fuel saving and lower engine noise.

- Command Limiter for machines working at low speeds with high engine speed (e.g. approach mode):

- Better machine manoeuvrability

- Driver Presence increases the safety at the worksite, preventing machine from moving without a driver.

- Accelerator Joystick function that is mostly used in tractors’ control agronomy:

- Smooth joystick control of requested speed

- Control of acceleration and deceleration levels

- System protection functions (over-power protection, over-pressure protection, over-temperature protection, over-speed protection) to preserve hydraulic components and increase the lifetime of the machine.

- Safety start management for safer work. It ensures that all required safety conditions are met before allowing the machine to move.

Customizable and easy to use

SmartDrive™ is designed for easy programming, parameterization, personalization and diagnosis. It can be applied to many different applications through a programming tool CT-SUITE.

Beside standard functions, we also offer customized customer-specific application software based on the SmartDrive™ modular system that is in-series production-ready as pre-installed software for SmartDrive CT electronic control units. Some application specific systems are available with pre-defined software, e.g. Skid-Steer System.

As hardware we use SmartDrive CT electronic control units.