WHO IS FIXING MY MOTOR? WESLEY, WORKSHOP EXPERT, UK

A mechanical engineering course done as part of my GCSEs piqued my interests in the industry – helping me to decide that this is what I was looking for when I left school...

A mechanical engineering course done as part of my GCSEs piqued my interests in the industry – helping me to decide that this is what I was looking for when I left school. I started with Poclain as part of an advanced apprentice program, training on-the-job for my current position managing our UK Certified Repair Center. My course of study consisted of hybrid practical and classroom learning. This allowed me to learn theory and apply it during my apprenticeship getting me ready for the job. Most recently, I had the opportunity to welcome an apprentice from the same program in the shop as a mentor. [The program] has helped him progress along quite nicely, which you can see in his work now. Doing this gives me the opportunity to relearn the subjects from a different perspective.

We asked Wesley what a normal day is for him, and found out a normal day for Wesley is anything but. The one thing he’s sure of when he gets his overalls on is that every day is different:

Inspections, creating and sending repair reports off to the customers and corresponding back with them on how they want to proceed. Then maybe doing some repairs or getting on the phone with customers – it’s never the same.

When repairing a motor trust plays a big part. Wesley makes a point to talk with the customer to get as much information as possible – something that they might not be comfortable with if they didn’t trust his expertise. We asked Wesley how he goes about a repair:

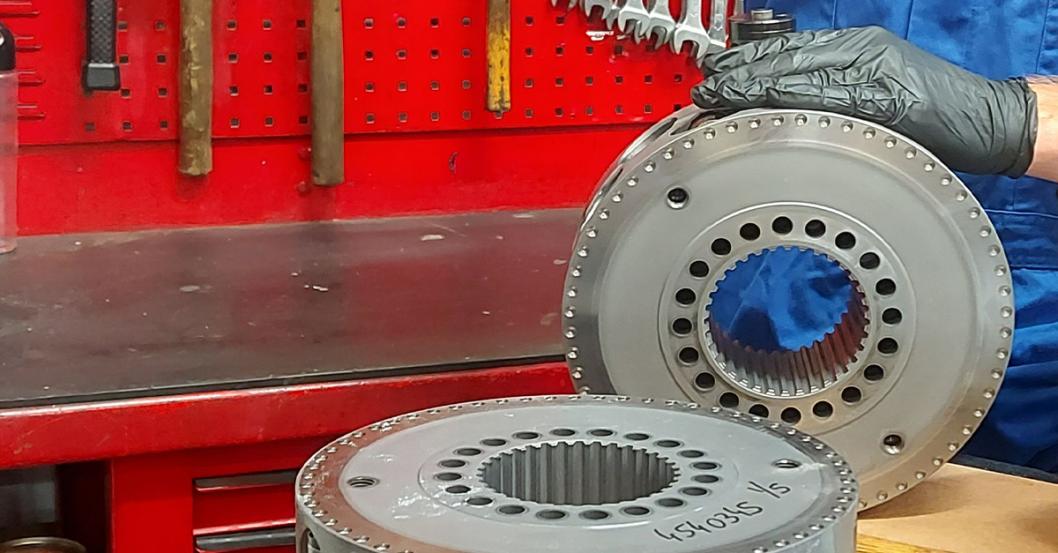

Depending on what the customer says that they are experiencing with the motor, Wesley has a pretty good idea of where to start. Once the motor is in the shop – the team takes it apart and does a visual inspection of everything. Usually this is enough to figure out what is wrong and give me the information needed to enter that into the RMA system. I then complete the inspection report with photos for the customer.

According to Wesley – earning the customer’s trust is the key to helping them. During our interview, Wesley gave us some insight into the challenges and rewards of having a customer-oriented position:

Some customers are very keen on getting a lot of test reports back and meeting their standards on that is quite a challenge sometimes. I handle this by doing the reports for them – telling them about certain leakages at certain flow rates. I often make a point to explain it to the customer over the phone as well, or sometimes we will have customers come in to visualize what we are saying. Usually we are able to get to the end product that way. Some customers are really into it – they really want to know everything. Relationships with the customer is a big thing. Because once you have built up that relationship, you can trust them and they trust you. It’s then easier to get the whole job complete, because we work together better. I spend a lot of time on customer relationships- emails, calls, and visits.

Since customer visits are such a big part of what Wesley does – we asked him to share a typical example:

It’s not so much repeat customers, but the local farmer down the road coming in to see if we could please help them out. They are the ones that really want to understand what is going on with their motor. I demonstrate it for them, and the customer goes away really happy and with a better understanding. They are the ones who tend to tell their friends, colleagues and others about the experience they have had, which helps grow our network of customers. Trust is a big thing, and our customers trust us enough to recommend us to their friends.

For fun, we asked Wesley about what he likes to do in his free time – and just like his days in the workshop, his answer was anything but typical:

I haven’t really got any hobbies or interests currently. I did have a lot of interest in the motor trade/cars that sort of thing. It’s because recently, I bought a house. So a lot of my time is spent painting and repairing things there. It’s interesting because, with the job I do, a lot of the tools that I learned to use and knowledge I gained can be applied to the repairs I am doing on the house. It’s strange because, you wouldn’t think so, but when you know how to use the tools correctly from working in the workshop, you can use that at home to repair other things. So, like for instance, a water pipe turns into a hydraulic hose in your mind. It’s the same thing. It’s still transferring fluid.

When we asked him if there was anything else he would like to share with our customers, Wesley said “It’s nice to put a name to a face – don’t hesitate to phone or email”.

Trust and confidence play a big part in who you choose to repair your Poclain Hydraulics parts. Poclain Hydraulics internal certified repair centers meets our stringent guidelines for quality and reliability across the globe. Whether it is a motor or pump, you want to know that someone who understands your machine and your needs is handling your components correctly and efficiently.

Poclain Hydraulics UK Certified Repair Center is located in Oundle, Peterborough, Cambs and you can reach Wesley by phone at +44 1832 277404 or our contact-us form.