Unrivaled Motor Efficiency For Next-Gen Skid Steers

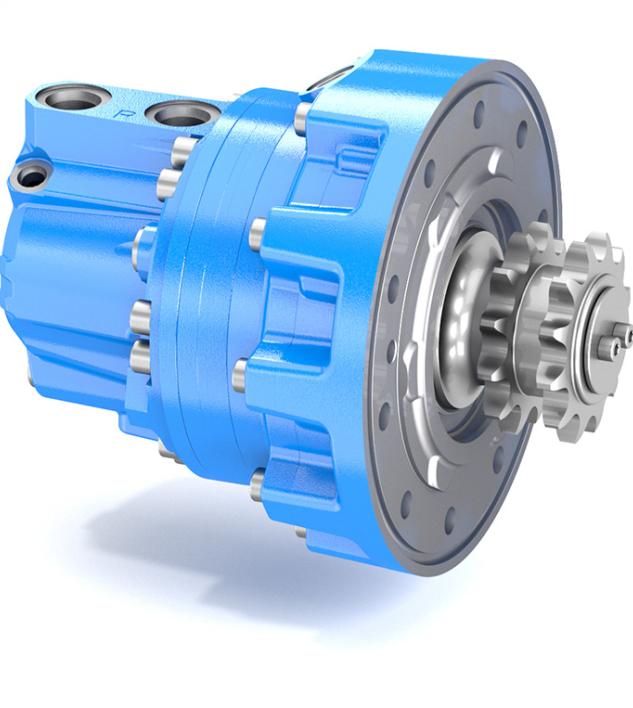

ML06 and ML04 share certain components, including a dual sprocket, a cam, and a claw brake. However, the ML04 outperforms its predecessor in terms of efficiency.

Skid steers are one of the toughest machines on the jobsite, working fast, turning in tight spaces, reversing, lifting, digging, and drilling. Their long workdays call for a diesel engine paired with hydrostatics and their strict emission requirements for a revolutionary high-efficiency design – Poclain’s ML04.

The ML04 is currently undergoing endurance tests in our facilities. It will go into production at the end of 2024.

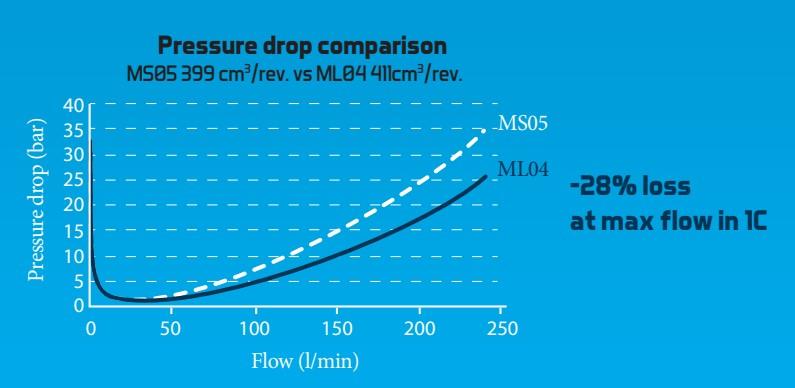

We developed the ML04 in conjunction with leading skid steer OEMs. Our high torque technology has always surpassed gerotors and high speed and gearbox assemblies in terms of efficiency. With the ML04, we have pushed the envelope further. Its efficiency is 28% higher than the previous generation MS05.

The ML04 takes skid steer performance to the next level

The ML04 integrates design improvements that simplify logistics as well as improve machine performance and emissions.

ML04 features

- From 262 to 447 cm3 / rev. [16 – 27 cu.in / rev]

- Single or two-speed

- 1.5 two-speed ratio in line with skid steer travel speed

- Integrated flushing

One part number for the two-speed version

Thanks to symmetrical valving, the left and right motors share the same part number for simpler inventory and programming.

Unprecedented efficiency

Its new valving architecture enables minimal resistance to the oil flow, increasing efficiency and limiting emissions and fuel consumption.

High performance

With a max power of 25 kW [33 HP], the ML04 can deliver double the power of the previous generation MS05. It generates less heat and tolerates higher travel speed and pressure. It enables OEMs to downsize cooling and hydraulic components and operators to be more productive on the jobsite.

Reinforced sealing

Exposed to the oil that churns inside the skid steer’s chain case, the ML04 is designed with a reinforced sealing that ensures leak-free interfacing.

For any inquiries, please reach out to your Poclain sales contact.

Sylvain MICHON

Project Manager at Poclain Hydraulics

Contact us

Visit us on Agritechnica, Hannover, Germany, November 12-18, booth #B16, hall 16