Step Up to Hybrid with Poclain

The pressure to reduce emissions and fuel consumption in Non-Road Mobile Machinery (NRMM) is stronger than ever. Stricter regulations, rising fuel costs, and increasing demand for cleaner operations are reshaping the industry. While full electric solutions hold promise, they remain limited by battery size, weight, and autonomy constraints — particularly in heavy-duty applications.

Why Hybrid?

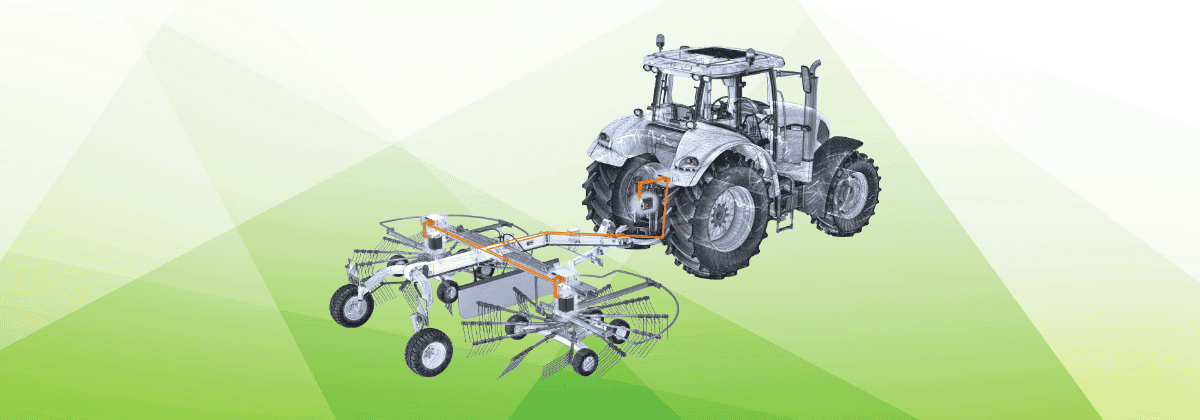

NRMM presents unique challenges. Tractors, excavators, harvesters, and other heavy-duty equipment operate for long hours in demanding environments. Providing sufficient energy storage using batteries alone often leads to impractical solutions — oversized, heavy, and expensive machines that compromise usability.

While hydrogen and full battery-electric solutions are advancing, hybrids currently offer the best compromise between performance, cost, and sustainability for heavy-duty applications. By combining the robustness of traditional internal combustion engines (ICEs) with the efficiency of electrified functions, hybrids provide a pragmatic, efficient, and scalable path forward — delivering tangible benefits in sustainability, productivity, and operating costs.

System Architecture

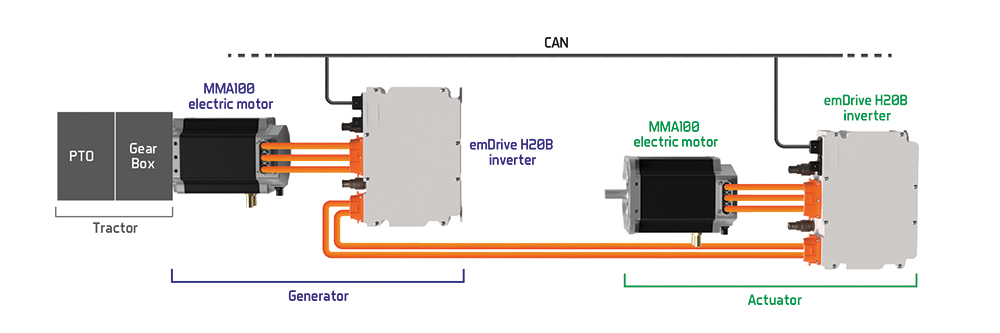

A typical hybrid transmission for NRMM consists of:

- An internal combustion engine (ICE) driving a generator

- A DC bus serving as the backbone for electrical power distribution

- Electrified functions, such as traction, auxiliary systems, or embedded tools

- Energy management ensuring optimal allocation of power and smooth shifting between ICE and electric modes

The decentralized architecture enables each actuator to draw only the power it needs, reducing energy losses compared to centralized hydraulic systems.

It can be enriched with a buffer Li-Ion battery system interfaced between the DC Bus inverter and the electric actuators, thus bringing further optimizations as well as additional working modes:

- Operate the ICE at its most efficient working point (RPM/torque point); at low power workload, it can even be disabled

- Offer a zero-emission mode for indoor applications, relying purely on battery power; this opens the path to plug-in hybrid design, if an onboard charger is added

Hybrid Solutions Bring Operators Key Benefits...

- Fuel and emissions savings: Up to 30% less diesel consumption translates into lower operating costs and reduced carbon footprint

- Increased productivity: Reduced noise and vibration enable longer daily operation and higher operator comfort

- Simplified maintenance and reduced costs: ICE Service intervals are extended, electric components are natively self protecting and enable faster diagnosis and servicing thanks to their connectivity

And Strategic Value for OEMs

Hybrid solutions are a strong differentiator and align OEMs with the increasingly strict environmental regulations. Their high adaptability makes them compatible with a range of voltage levels, applications, and machine sizes. They also offer a future-proof transition toward full electrification when battery technologies mature.

Hybrid transmissions represent a powerful transition technology for non-road mobile machinery. They reduce fuel consumption, cut emissions, improve operator experience, and simplify maintenance — all while preserving the reliability and autonomy of diesel-powered machines.

Poclain’s Hybrid Expertise

Poclain has developed a portfolio of solutions tailored for hybrid Non-Road Mobile Machinery (NRMM) up to 870VDC systems. They target the electrification of tractor-mounted implements and auxiliary systems in forestry and mining equipment, as well as the hybridization of low-power drivetrains in compact construction machines.

Key advantages include:

- High Efficiency Architecture: Thanks to unique control software, excellent DC link stability and eMotor control

- Simplified Mechanical and Electrical Integration: Even in tight spaces, thanks to highly compact inverters, e-motors and generators with adaptable interfaces

- Simplified System Integration: Communication is CAN-based (J1939, CANopen) and uses the UDS protocol for diagnostics, flashing, and preventive maintenance; it complies with off-road machinery functional safety standards such as ISO 25119, and can host customer application software in its inverters

- Rugged Components and Connectors: Designed to meet the harsh conditions of off-road applications; the sensorless control option is also available for greater resistance to shocks and vibrations.

Philippe REYNOLDS

Poclain Electromobility Program Director

>> Download the brochure Electrification Innovation Made Easy

>> You can also read this article in this issue of the magazine OEM Offhighway