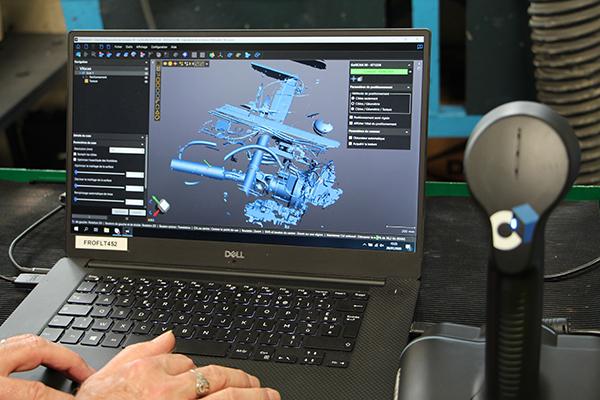

POCLAIN HYDRAULICS STEPS UP PROTOTYPING WITH A 3D SCANNER

From scan data, Poclain experts generate CAD files of the vehicle or machine’s hydraulic components or systems envelope. This helps eliminate cardboard models and on-site adjustments. The scanner’s precise measurements allow for a resulting prototype that looks and behaves like the series version.

Thierry Thébaud, Systems Designer at Poclain Hydraulics, shares his experience with the 3D scanner “In the beginning of the year, I used it on a truck prototype in the US. The shaft output angle was particularly tricky to measure, and the 3D scanner enabled me to model the motors’ integration with 100% accuracy–it took a lot less time for me than the client would have needed if they had gone through a mockup phase”.

Three levels of service are possible incorporating 3D scan technology.

Level One – 3D Machine Environment Scan

Poclain scans the machine on location reducing logistical coordination and generating 3D files of the environment in which the hydraulic components and/or systems will be integrated. Poclain Experts trained in scanning complex environments and 3D file post-processing software then manage the digitalization process:

- Machine preparation and surface scanning

- Cleaning and merging scanned files

- Creating reference elements including functional surfaces and verifying geometries

- Converting the scan to CAD interchange format

Once completed, Poclain Hydraulics delivers the customer the 3D files for hydraulic system integration study.

Level Two – Hydraulic Component Integration

At the second level, Poclain Hydraulics experts support 3D integration of hydraulic components into the machine’s digital environment. Starting with Poclain Hydraulics level one service or the client’s own 3D scans, Poclain analyzes the interfaces to support machine development, delivering:

- A hydraulic component integration study in the machine’s 3D environment

- Dimensional verification

- A report on integration interference observations

Level Three – Full Hydraulic System Integration

Taking level two’s component integration further with full hydraulic system integration, level three integrates all hydraulic components and system architecture into the 3D digital prototype environment. Poclain accompanies clients throughout the full digital prototyping process:

- A state-of-the-art integration study of the hydraulic components and system architecture in the machine’s 3D environment

- Dimensional verification and clarification of integration interferences from component level to full system integration

- Report on technical design recommendations to support machine prototype production

It is also possible to take into account different prototype environments such as different configurations or variants in the machine range.

To learn more about Poclain Hydraulics 3D scanning services or determine what service level could work for your project contact:

Anthony Gallais, Services Program Manager