Poclain Expert Report Secures Your Next-Gen Transmission

Assessing the duty cycle and energy requirements of a machine is crucial when designing or shifting to a new transmission technology, like electrification. You need to collect extensive field data to qualify and time each duty cycle mode. Once the raw data is collected, intricate modelling is necessary to establish a foundation for sizing components.

Leveraging more than 50 years' experience in a wide array of off-road transmissions, Poclain introduces the Expert Report service. It models a machine's duty cycle data and helps OEMs design or optimize their next-generation transmission.

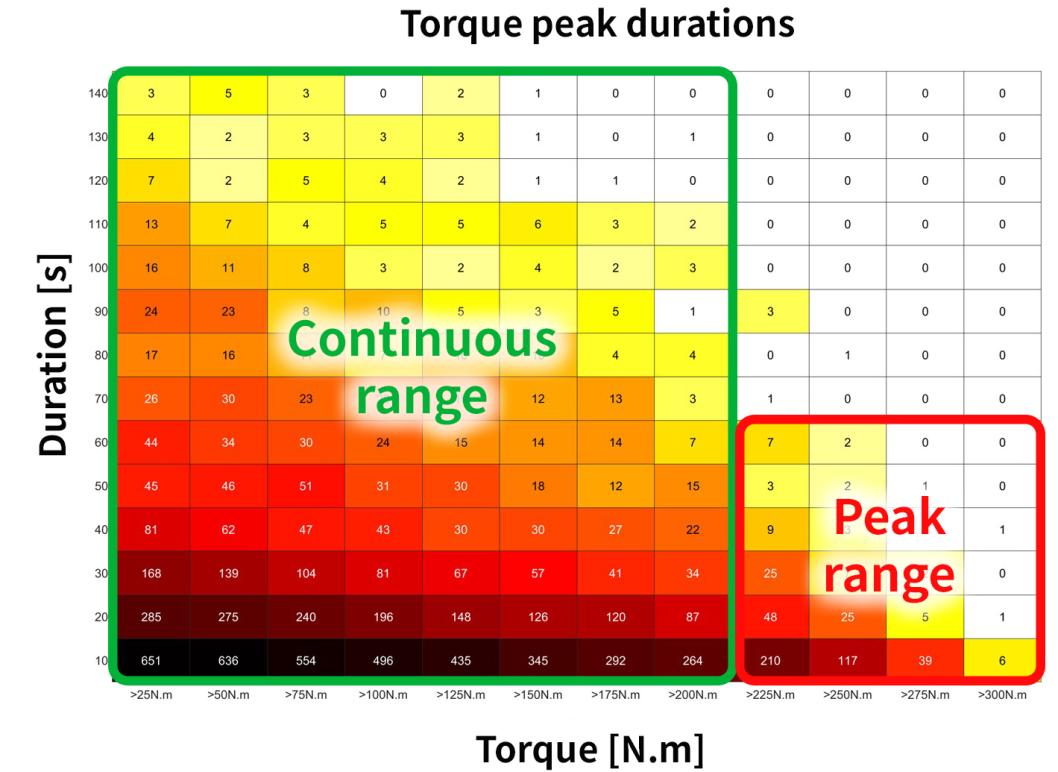

What are your machine's requirements in continuous versus peak usage ?

Poclain's data scientist team can analyze your own data, or propose a solution to collect duty cycle data on your machine in order to accumulate the data volumes that will allow in-depth analysis of machine performance. Central to the analysis is understanding your machine's characteristics during continuous versus peak usage, ensuring that component sizing prioritizes the former, while also withstanding the latter.

The duty cycle data feeds charts that measure the time spent in operation based, for example, on slope angle, speed, circuit pressure, engine speed and power, tractive versus resistive motion, or braking. Crucially, analyzing each dataset against the others is pivotal to appropriately size transmission components, focusing on meeting the requirements for end-user usage.

Electric motor sizing

Poclain's data scientist team focuses on measuring transmission and auxiliary power consumption and segmenting continuous versus peak modes. Essentially, this involves determining the power range used for the longest duration. The next-gen transmission is sized to optimize performance within the continuous range while still having the capacity to deliver additional power during peak periods.

This chart displays the time spent according to the torque level. The most frequent torque levels are grouped in the continuous range, while the exceptional torque levels are grouped in the peak range.

Energy profile and battery sizing

Based on the mission and the energy profiles, simulations are carried out with different charger sizes to ensure that all operating and energy consumption profiles can be covered. Battery size recommendations are made based on the actual operating modes of the machine. Besides the fundamental calculations, unforeseen vehicle data can emerge, such as excess heat in the circuit and oversized transmission components. They will be integrated into the vehicle recommendations.

Forestry harvesting heads, sprayers, mini-loaders, mining trucks, railway equipment and shredders are some of the applications that OEMs have analyzed using Poclain’s Expert Report service. Partner with Poclain for your next transmission design and gain a new insight into your vehicle’s usage and performance, empowering you to streamline your components or transition to new transmission technologies.

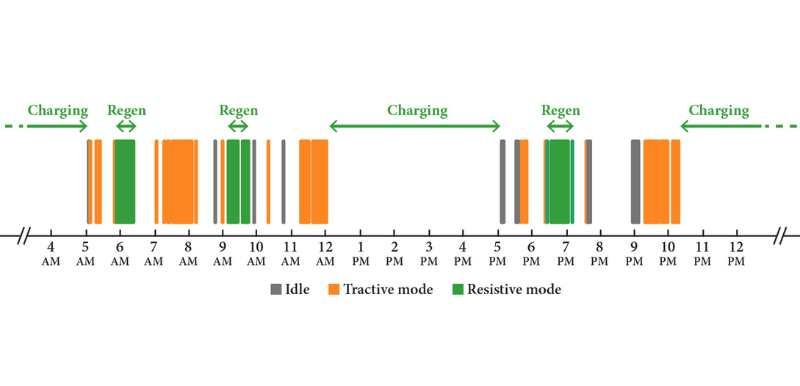

Mission profile

The team analyzes time spent in tractive and resistive modes, in other words driving uphill, downhill or braking, as well as periods when the machine is idle or parked, like during the lunch break or shift change. The good understanding of the mission profile and power consumption makes it possible to determine the appropriate battery size for the application.

This chart details the time spent in one day in tractive, resistive, idle and parked modes to define the charging pattern and battery size.

Serge Nicoloff,

Service Program Marketing Specialist

For more information, contact us

Visit us on Intermat, in Paris Nord Villepinte, from April 24 to 27, booth #EXT5 - G038.