The New Generation Of Drilling A Joint Success For Tracto and Poclain

Horizontal Directional Drilling (HDD) is an approved method for installing new infrastructure. Optical fiber for highspeed internet, water- or gas supplies in urban and rural areas are made with HDD to avoid conventional digging. This means less damage and also helps saving costs, time and energy compared to using an excavator. The new GRUNDODRILL JCS/ACS series from TRACTO sets a milestone in the power range of 130 to 300 kN pulling force with innovative features making it flexibly applicable in any type of soil.

Diverse ground conditions

Diverse ground conditions require different technologies for an effective work. The Jet Condition System (JCS) can be used for normal soils using the standard rods. The Poclain Hydraulics cam lobe motors are used here since they are tailor-made for this application in terms of speed, torque and power-range. This is nothing new and they were installed in previous machines as well. If the soil becomes hard and rocky, the All Condition System (ACS) comes into play. A co-axial twin-tube rod is now used for crushing the rocks, steering the drilling head and flushing. Before introducing the new GRUNDODRILL series, complex gear-box systems had to be used to realize the co-axial drive. This was a costly, bulky and heavy solution which also required extra maintenance for servicing the gear-box oil.

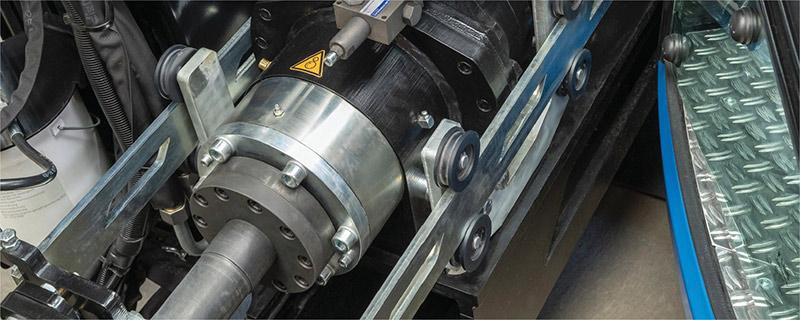

Drilling unit with Poclain Hydraulics high performance motor

"The basic idea came from Tracto. Our target was the elimination of the very special and bulky gear-boxes. We approached the application engineering of Poclain Hydraulics, located not too far from us in Pfungstadt, Germany. Several technical meetings were held but we found a promising direction after short time. Some adaptations needed to be done in detail, but most parts came off the shelf. Testing the prototypes with support of Poclain Hydraulics field technicians proved the performance in practice," Lucas Jostes, Tracto Chief Engineer Hydraulic, said.

The Poclain Hydraulics MS series always allowed the use of hollow shafts. For extra power, a special version of our MHP series is used here for additional speed and lifetime. Two of those hydrobases in a row allows the rotation of the co-axial twin-tube rods plus the additional passage for the flushing. This makes the whole machine layout unbeatable in terms of slimness and low weight.

The basic hydraulic components are from the Poclain Hydraulics standard MHP. However, the demanding application required some adaptation and alignment to fulfill TRACTO´s needs.