[Case Study] Jacto and Poclain Pave the Way for Coffee Harvesting in Brazil

With a culture steeped in innovation, Brazil-based Jacto made history in 1979 by introducing the world’s first mechanical coffee harvester, the K 3. Forty-five years later Jacto remains the leading brand in coffee harvesting machines in Latin America.

Their two machines, the K 3000 and the K 3500, sport a Poclain transmission, the result of a strong collaboration rooted in technical excellence. Jacto’s founder, Mr. Shunji Nishimura, experienced firsthand the hardships of coffee harvesting while working in the plantations, spurring him to invent the first self-propelled coffee harvester. The company’s current machines carry forward his spirit of innovation, integrating advanced features such as lateral slope correction and telemetry to ensure optimal yield and agile maneuvering in the most challenging terrain.

A Legacy of Ingenuity

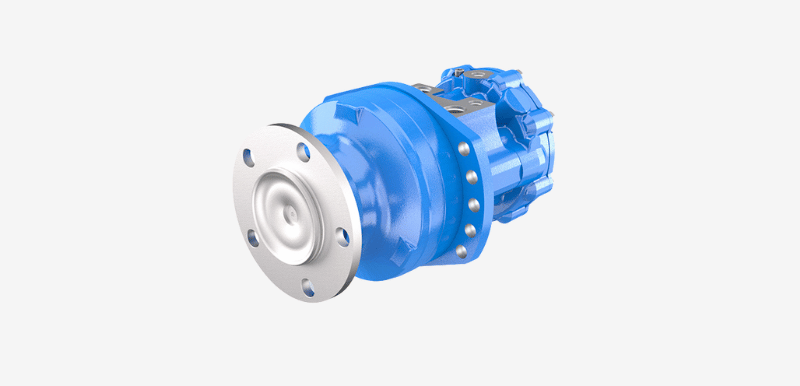

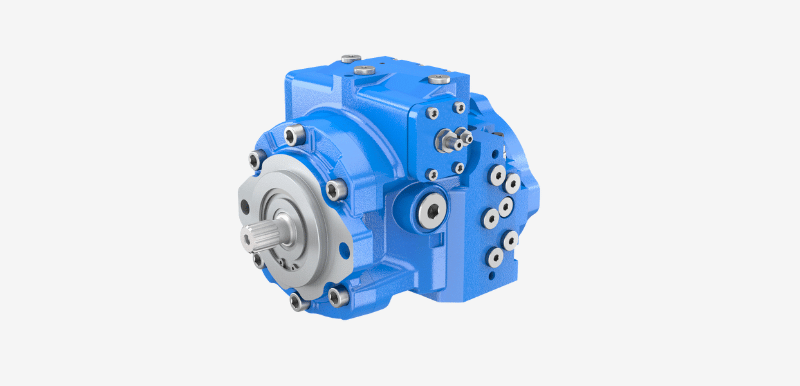

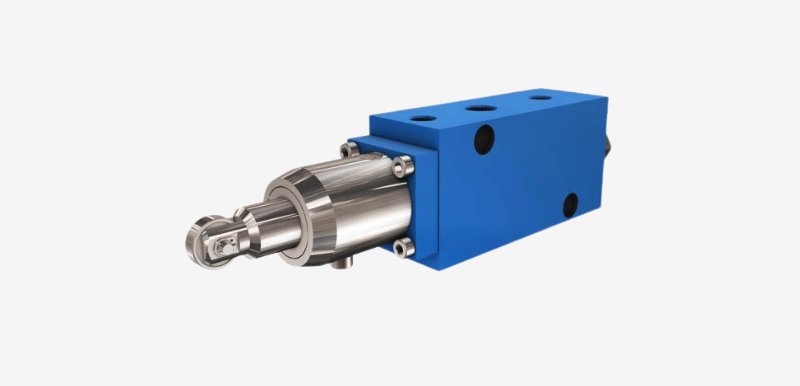

The three-wheeled K 3000 is driven by three MSE08 motors in a TwinLock™ circuit to provide permanent antiskid, as well as a PM30 pump. Designed for larger-scale plantations, the larger four-wheeled K 3500 machine sports two MSE11 with TwinLock™ and two MS08 motors on the front. Poclain’s TwinLock™ permanent hydraulic traction control system is a key feature of the Jacto machines, enabling operation on slopes of up to 30%, common in regions like southern Minas Gerais and the interior of São Paulo. In addition to TwinLock™, the transmission integrates a VDP valve to adjust the flow between left and right to ease turning and prevent damage to the ground.

Collaborating with Poclain has been essential in overcoming the technical challenges related to mobility and traction on uneven terrain

Jacto and Poclain Partners in Leading-Edge Technology

Together, Jacto and Poclain have engineered solutions that meet the actual needs of Brazilian coffee farms, with superior performance and lower environmental impact.

The coffee mechanization market is constantly evolving, with new demands such as mechanizing the harvest of the various types of conilon coffee bean. The partnership with Poclain will be strategic in continuing to innovate and deliver solutions that keep Brazil at the forefront of global coffee production.

An interview with, Paulo Bueno, Jacto Business Manager

To know more, contact us