[Interview] Poclain’s Electro-Hydraulic Transmission Stands Out On The Test Track

Benjamin L’Hénoret is Poclain’s new Marketing Manager for Electromobility. He shares the simulation data for Poclain’s new electro-hydraulic solution, and where it stands against existing zero-emission transmissions.

Poclain is very active on solutions and components for zero emission vehicles. What new products are you launching on the market?

Poclain has developed e+h, a system offer for zero-emission electric vehicles. This semester we are launching our new e+h single electric motor solution, for which electric components are associated with high-performance hydraulic wheel motors. The system is designed so that only one motor is used for propulsion and auxiliaries, leading to a simple and cost-effective solution. The newly proposed architecture includes emDrive inverters from our sister company EmSiSo, which joined the Poclain group in 2022. This solution will allow OEMs to enter the zero-emission market with cost-competitive high-performance machines.

How does this new e+h solution stand out?

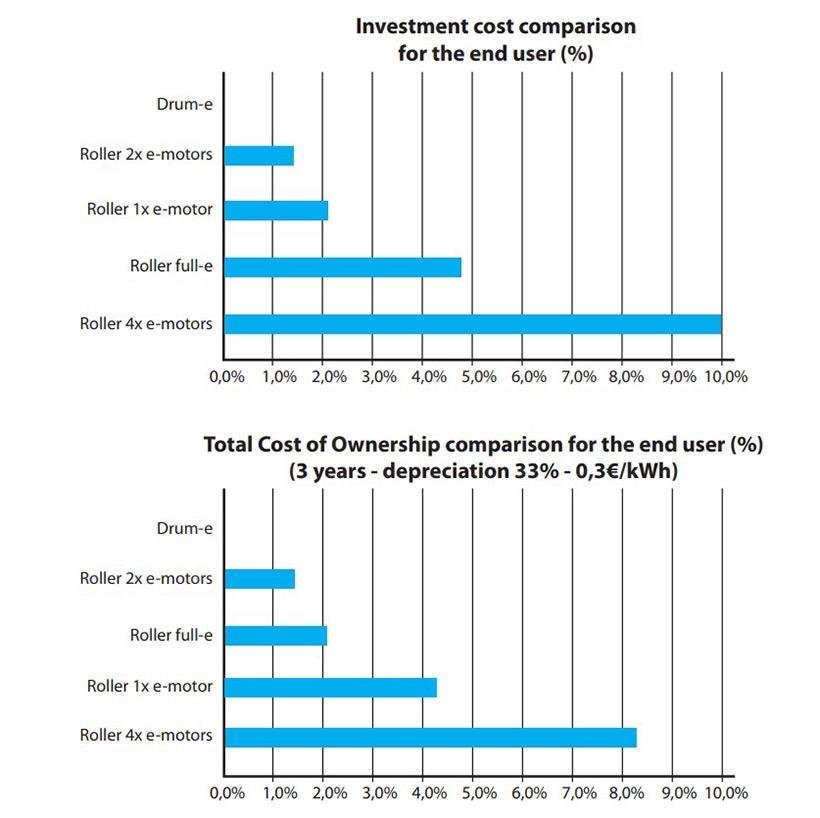

Simply by offering the best compromise! Electrified solutions should be designed to offer a good performance over cost ratio. As an example, let’s take the «Drum-e» demo tandem roller we built. «Drum-e» is based on a single e-motor architecture with the e-motor driving two closed loop pumps, one for propel & one for vibration. We benchmarked it with four transmissions that are currently available on the market.

For each system, our team was able to estimate the total cost of ownership thanks to a technical analysis and energy consumption. The models were correlated with testing results based on a representative duty cycle and field measurements with the help of our connected engineering team. Results demonstrate how well our solution performs in terms of overall cost in this duty cycle range. Thanks to a competitive cost compared with full electric solutions and a good system efficiency, the e+h architecture is the ideal solution for customers looking for the best total cost of ownership.

In a nutshell, what are the benefits of using Poclain’s new e+h one electric motor solution?

The hybrid electric + hydraulic solution is ideal for compact machines that are not intensively used. Out of an eight-hour day, the machines typically stay idle or stopped for part of the day. They rarely work more than three to four hours a day. Hence, e+h solutions are perfect for applications where overnight charging is the norm and partial day charge possible in case of more intensive usage. Besides being an efficient solution, Poclain’s e+h architecture offers:

- Zero-emission and low noise

- The same performance as the current diesel version

- High ruggedness

- Seamless integration onto the current chassis

- Reduced development costs

- Low manufacturing investments

- Short time-to-market

Roller e+h 1x e-motor: Closed loop propel / Closed loop vibration

Roller full-e: Full electric transmission

Roller 2x e-motors: Closed loop propel / Open loop vibration

Roller 1x e-motor: Closed loop propel / Open loop vibration

Roller 4x e-motors: Closed loop propel / Open loop for auxiliaries / 2 e-motors for vibration

What are the next milestones at Poclain for electrified vehicles?

Working on efficient solutions is Poclain’s DNA, and we aim to make the e+h solution the best compromise for more and more applications. Thanks to our transmission expertise and the experience we have gained in electrification projects, we can support our off-road customers by providing a validated and competitive zero-emission solution in less than 12 months.

Do you want to know more?

Visit us on Agritechnica, Hannover, Germany, November 12-18, booth #B16, hall 16