Higher Efficiency, Lifetime, And Speed With The Poclain Hevo Dual Motor

The new MHD motor is aimed at applications that require high productivity where the motor should run at high speed while providing sufficient torque, energy efficiency and lifetime. It is primarily aimed at tools such as drilling heads, forestry harvesters process rollers and could also benefit trencher, shredder and propel applications that require multiple speed ratios.

The name MHD stands for Motor Hevo Dual. Hevo is the name for the next generation of cam lobe motors at Poclain and Dual embodies the fact this motor has been designed to be a native dual displacement motor with the aim to bring its best performance when operated in its smaller displacement.

With the HEVO design, running in small displacement is much more efficient both at the component and system levels. At the component level, Poclain has reinvented the oil distribution to the radial pistons, greatly reducing the pressure dro at high speeds. At the system level, operating a motor in small instead of large displacement allows to reduce flow and increase pressure, thus boosting efficiency. For torque peaks the large displacement remains available when needed. With native two displacements architecture and high efficiency performance at very high power, MHD drives one essential benefit: higher productivity by getting more done in less time.

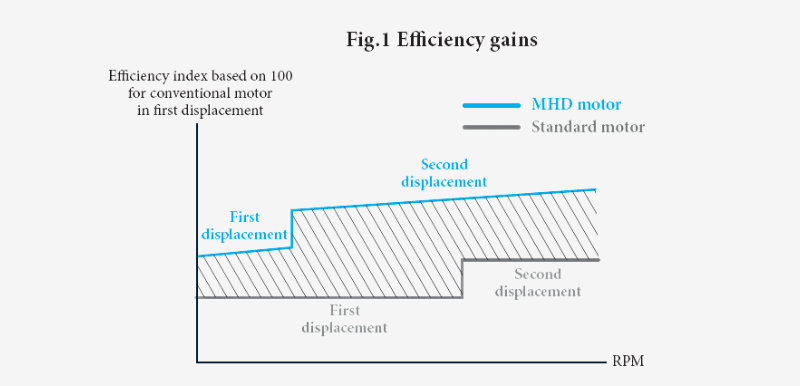

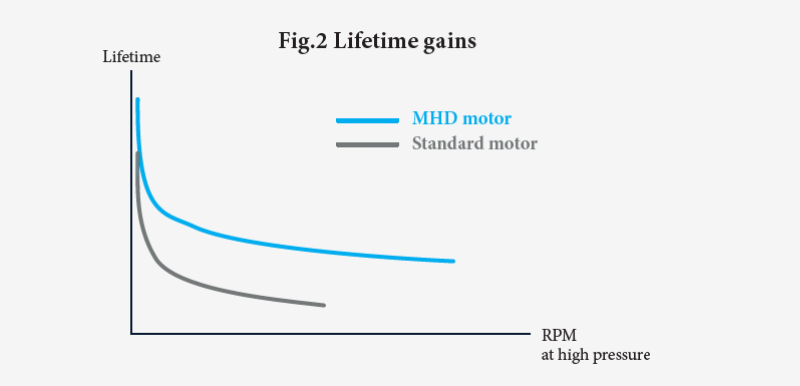

Figure 1 illustrates the double efficiency gain of the MHD: the blue curve is above the grey curve since the HEVO motor has higher efficiency than the standard motor, especially at higher speed; and the HEVO motor can work for longer time in small displacement because the lifetime in small displacement is higher. With the new dual technology, all pistons and all cams stay active in the small displacement mode, thus allowing the torque load to be distributed between more mechanical parts compared to Poclain’s standard torque module architecture.

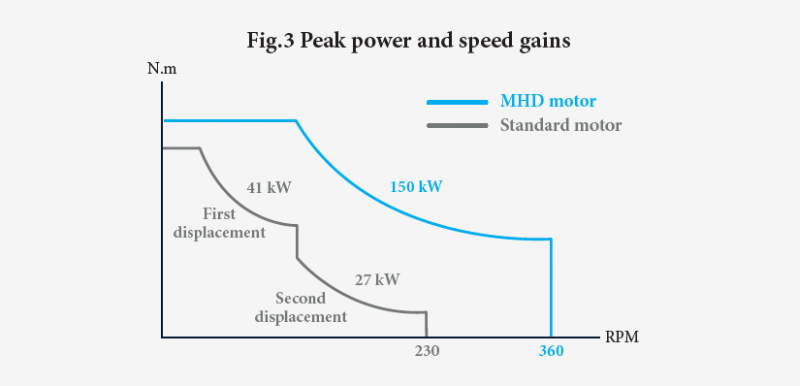

Likewise the power that can be supplied by the motor stays high in small displacement. These two gains in lifetime and power in small displacement are emphasized in figures 2 and 3.

The MHD09 with a displacement range of 36.7 to 59.7 cu.in/ rev. (602 to 978 cc per rev.) will be in series production in the third quarter of 2026 and it is qualified for 150 kW power. It is the first model of a series that should cover more displacements and provide various ratios between large and small displacements.

Know more about the HEVO technology