CREEPDRIVE AT CONEXPO-CON/AGG | IFPE 2020

Poclain launches the new CreepDrive™ 2 system, helping the end user to maximize productivity, work quality and driver comfort. Likewise, the system is optimized to facilitate installation on the chassis. It’s not only about increasing the performance in terms of speed and torque!

The CreepDrive system, a true hybrid mechanical hydraulic transmission, allows vehicles to work at very low constant speeds regardless of the engine speed, providing auxiliary systems with the power they need to perform work effectively. When the vehicle drives on the road in non-working mode, CreepDrive is totally disengaged, allowing the vehicle to reach the max vehicle speed and at the same time, preventing any mechanical losses.

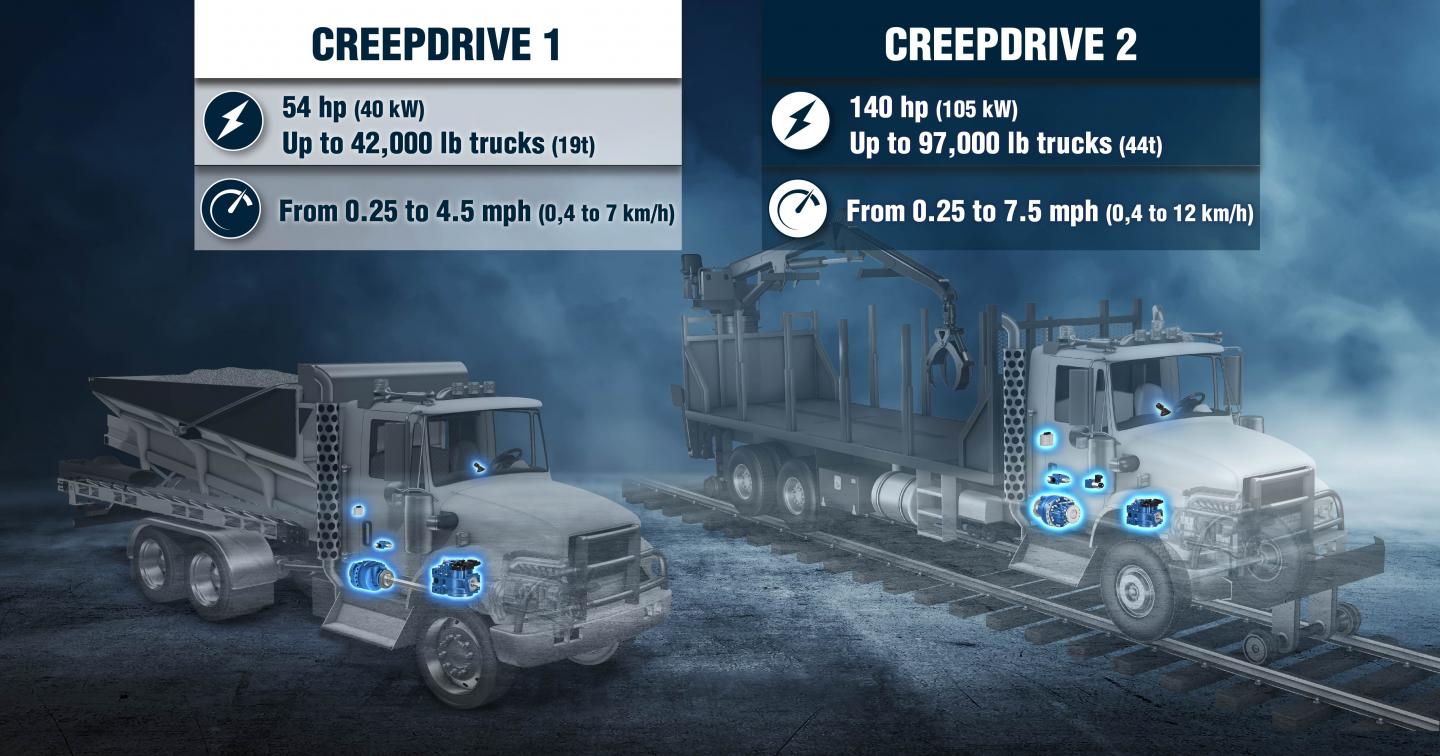

The complete CreepDrive lineup contains two different sizes of motors, a range of pumps, valves and the plug & play control kit including the CAN bus communication. The new CDM20 motor provides up to 2.4 l (122 cu.in) of displacement with two speeds (possibility to switch from full to half displacement).

In conjunction with the gear reduction ratio in the rear drive axle differential, the CDM20 can provide an overall torque ranging from 36 000 to 72 000 ft.lbf (50 000 to 100 000 Nm). Other new features include a reinforced shift cylinder as well as an extremely robust design. This new motor complements the existing CDM222 motor by offering twice the speed and three times as much torque.

CreepDrive removes the added stress on braking and clutching that trucks working at low speeds experience, as well as the additional maintenance required to keep those systems working properly. Replacing friction braking with hydrostatic braking, which acts as an integral decelerator reduces the need to feather the brakes. This allows for more precision and less opportunity for error, helping operators increase safety and productivity.

In addition, radial technology eliminates the need for an additional reduction stage and offers some of the highest efficiencies on the market. This reduces fuel consumption and noise, which is a key requirement for urban applications. Finally, an integration benefit - the CDM20 motor is fixed only on the one side of the chassis, which guarantees the original chassis flexibility.

CreepDrive 2 meets the needs of a wide range of applications such as road maintenance & road marking, concrete mixers, bridge inspection, rail track maintenance, airport & road sweepers, deicers, snow cutting, suction dredging, slinging and mulching/chipping machines, among others.

CreepDrive helps end users to maximize productivity, work quality and driver comfort, and is optimized to facilitate installation on the chassis.

The new CreepDrive system will be on display at CONEXPO-CON/AGG | IFPE 2020 this year in our booth S81613.

Learn more at our booth: add us to your show planner.

Visit us during the IFPE Fluid Power Happy Hour