Shredder

Environmental efficiency and Productivity

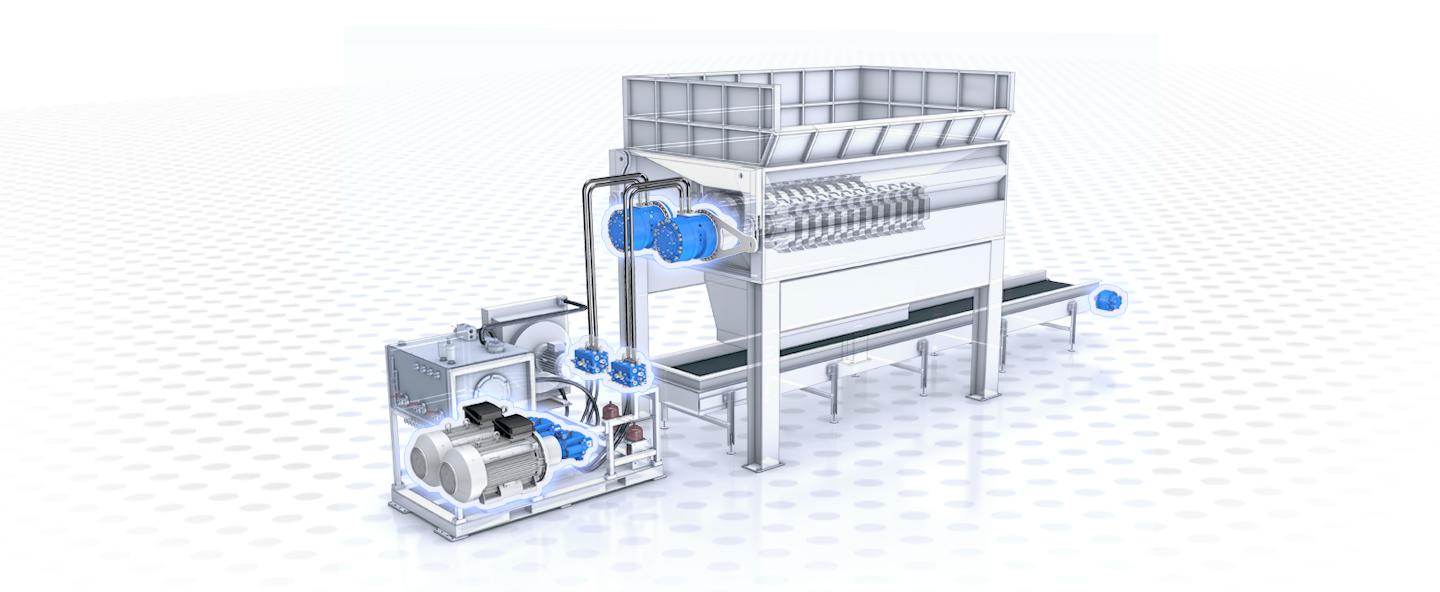

The reference offer focuses on maximizing the output of your shredder with the most efficient direct drive solution. This includes energy savings through higher efficiency, which not only enhances productivity but also reduces operational costs.

Easy Integration and Maintenance

With an emphasis on motor compactness, the solution offers easy integration into existing systems. Additionally, the design facilitates easy accessibility for shredding tool servicing, making maintenance simpler and more efficient, thus minimizing downtime and extending the equipment's life span.

Reliability and Robustness

The offer assures a proven solution for the most demanding and heavy-duty shredding applications, featuring proven direct drive technology and robust drive components. This reliability is further supported by comprehensive services such as commissioning, real duty cycle analysis, training, and access to a worldwide repair center network, ensuring long-term performance and support.

Benefit from Poclain expertise

- Poclain is the market leader in hydrostatic transmission

- Achieve your time-to-market goals with our long-term hydraulic shredder drives development experience

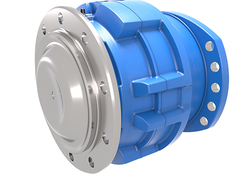

- Benefit from a simplified design with a compact, high-torque density solution

Choose your shredder solution

| SHREDDER INSTALLED ePOWER | OUTPUT TORQUE PER SHAFT | CONFIGURATION | MOTOR | SHRINK DISK | POWER TRANSMISSION VALVE |

|---|---|---|---|---|---|

| Solution for e-power 132 kW to 250 kW 177hp to 335 hp | 40000 Nm 29500 Lbf-ft | Shrink disk motor Torque arm fixation | 2 x MS83 | 2 x MS83 shrink disk | 2 x MS83 - Anticavitation block 2 x MS83 - Cross Over Relief Valve |

| Solution for e-power 132 kW to 250 kW 177hp to 335 hp | 40000 Nm 29500 Lbf-ft | Female shaft motor Torque arm fixation | 2 x MS83 | 2 x MS83 - Anticavitation block 2 x MS83 - Cross Over Relief Valve | |

| Solution for e-power 132 kW to 250 kW 177hp to 335 hp | 46000 Nm 34000 Lbf-ft | Shrink disk motor Torque arm fixation | 2 x MS83 | 2 x MS83 shrink disk | 2 x MS83 - Anticavitation block 2 x - MS83 Cross Over Relief Valve |

| Solution for e-power 132 kW to 250 kW 177hp to 335 hp | 46000 Nm 34000 Lbf-ft | Female shaft motor Torque arm fixation | 2 x MS83 | 2 x - MS83 Anticavitation block 2 x - MS83 Cross Over Relief Valve | |

| Solution for e-power 132 kW to 250 kW 177hp to 335 hp | 65000 Nm 48000 Lbf-ft | Shrink disk motor Torque arm fixation | 2 x MS125 | 2 x MS125 shrink disk | 2 x - MS83 Anticavitation block 2 x - MS83 Cross Over Relief Valve |

| Solution for e-power 132 kW to 250 kW 177hp to 335 hp | 65000 Nm 48000 Lbf-ft | Female shaft motor Torque arm fixation | 2 x MS125 | 2 x MS83 - Anticavitation block 2 x MS83 - Cross Over Relief Valve | |

| Solution for e-power 250 kW to 355 kW 355 hp to 476 hp | 83000 Nm 61300 Lbf-ft | Shrink disk motor Torque arm fixation | 2 x MI250 | 2 x MI250 shrink disk | 2 x MI250 - Anticavitation block and Cross Over Relief Valve |

| Solution for e-power 250 kW to 355 kW 355 hp to 476 hp | 83000 Nm 61300 Lbf-ft | Female shaft motor Torque arm fixation | 2 x MI250 | 2 x MI250 - Anticavitation block and Cross Over Relief Valve | |

| Solution for e-power 250 kW to 355 kW 355 hp to 476 hp | 130000 Nm 96000 Lbf-ft | Shrink disk motor Torque arm fixation | 2 x MI250 | 2 x MI250 shrink disk | 2 x MI250 - Anticavitation block and Cross Over Relief Valve |

| Solution for e-power 250 kW to 355 kW 355 hp to 476 hp | 130000 Nm 96000 Lbf-ft | Female shaft motor Torque arm fixation | 2 x MI250 | 2 x MI250 - Anticavitation block and Cross Over Relief Valve |

|

|

|

| Flexible Design | Productivity | Reliability |

| Easy integration thanks to motor compacness | Energy saving through higher efficiency | Proven direct drive technology |

Related Articles

See more